Close

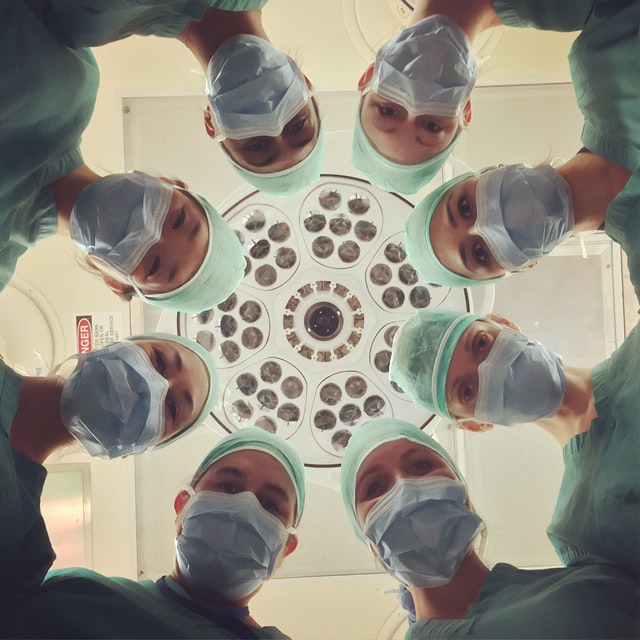

From face masks to non woven medical gowns and so much more, PPE items manufactured using Ultrasonic Sewing Machines are resulting in safer, more cost effective PPE solution to meet the global demand.

Ultrasonic welding sewing machines provide the necessary levels of hygiene required for the production of such vital PPE equipment as N95 face masks.

Because of how ultrasonic sewing machines work, they create a fabric join that can be made almost completely flat against the body and combined with seam sealing tapes, can become a lot stronger than conventional sewn seams.

While conventional sewing seams are and always will be a common site in clothing manufacture, ultrasonic welding is proving to be a superior alternative for PPE application. On traditional sewing machines, the needle punctures holes into the fabric, weakening its structure and providing ‘entry points’ for moisture and potential diseases to build up and pass through while the overlap of fabrics at the joint creates thick seams that are bulky, can restrict movement, are wasteful and adds weight to the garment. With our ultrasonic sewing machines, we can create a weld so small that it has to be backed with a seam sealing tape. Our standard weld created from an ultrasonic sewing machine is just 0.5mm!

And while traditional sewing stitches can wither and loosen, the bond created by an ultrasonic weld remains as strong as the fabric/material that it has bonded.

Ultrasonic welding can bond continuous seams for the likes of:

Ultrasonic sewing for PPE creates high strength, high integrity seam joins that do not require thread and they do not create the punch holes of conventional sewing (where micro organisms and contaminants can build up).

In a world constantly fighting the next wave of disease control, PPE is an ever increasing market place and one that can directly benefit from Ultrasonic Sewing Machines.

At Ardmel, we are Queens Award for Innovation Award Winners for developing ultrasonic sewing and cutting machine. Our experience in the field has seen us become one of the leading global manufacturers and suppliers of Ultrasonic technology for PPE application.

If you would like to know more about our range of Ultrasonic Sewing Machines and how they can directly benefit your PPE Manufacturing requirements, please contact our Global Head Office by emailing [email protected] or calling +44(0)1592 771 241

T: +44(0)1592 771 241

F: +44(0)1592 771 071

E: [email protected]