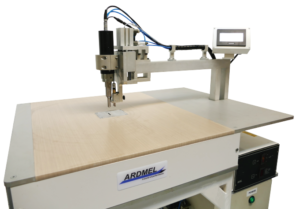

SMC-100 Ultrasonic Jig Cutter

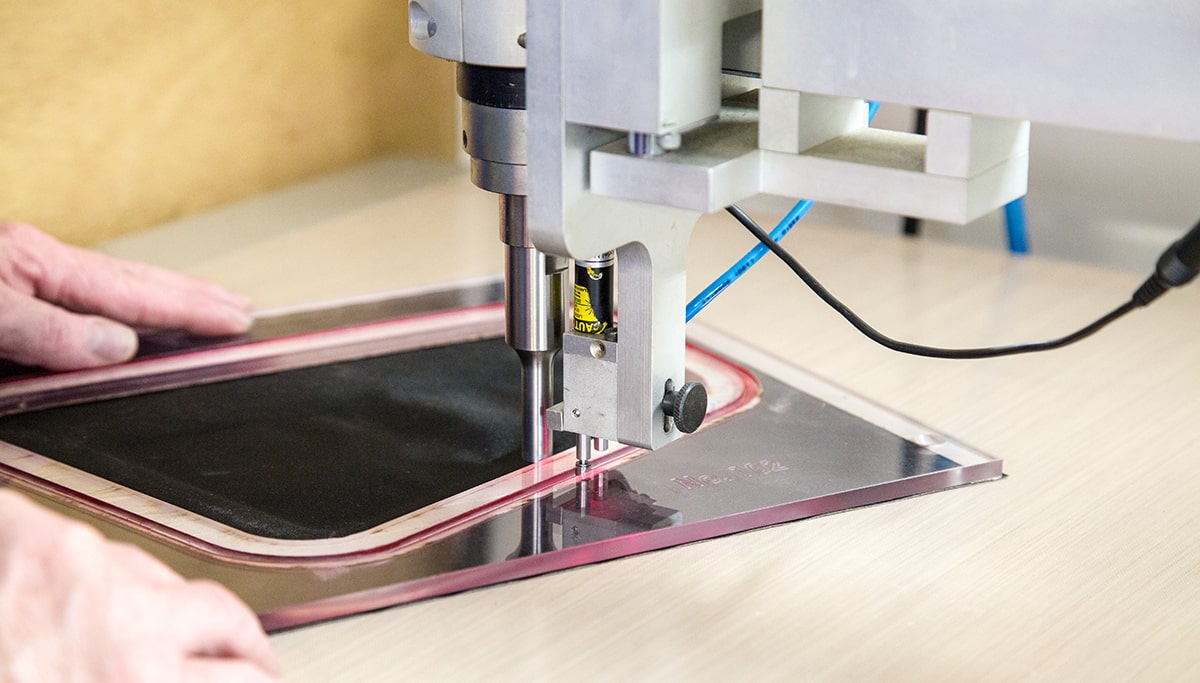

Designed to cut and seal a range of textiles (including 2-layer and 3-layer coated fabrics) with accuracy.

The clean edges are achieved by fusing them using sound waves. This method of cutting ensures no fraying, unlike laser which creates fibre bundles and beads that eventually break off during wear and washing, which is what causes the fraying.

Energy Efficient

Energy Efficient

Ultrasonic applications do not require any additives in the bonding area. The concentrated focus of energy allows optimum use therefore minimising energy loss.

The system uses heat which is generated via the high-frequency mechanical oscillations which are produced between the components as a result of molecular friction and boundary friction. The system is clean and safe with no emissions of cutting fumes such as smoke or toxic fumes from textiles.

APPLICATIONS

APPLICATIONS

| - Industrial textiles |

| - Filter fabrics (woven/unwoven) |

| - Polyethylene, Nylon, Polyester, Polyurethane |

| - Labels and ribbons |

| - Saree and ladies dress materials |

| - Lingerie |

QUALITY & ACCURACY

QUALITY & ACCURACY

| - The jig allows for ease and flexibility when cutting and is operator friendly |

| - The machine has the ability to cut various shapes and sizes |

| - The SMC-100 is designed to ensure ease of operation |

| - The machine uses a ZAPP steel sonotrode for optimum durability |

| - Continuous auto frequency tuning ensures perfect welding |

SPECIFICATION

SPECIFICATION

Machine Details |

|

|---|---|

| Power Requirements | - 230 V AC 50 Hz single phase |

| Pneumatic | - 7 bar at 60 litres/minute |

| Dimensions | - 850mm x 660mm x 1300mm |

| Weight | - 120kg (net) |

| Packed Dimensions | - 970mm x 750mm x 1410mm |

| Packed Weight | - 180kg |

Energy Efficient

Energy Efficient