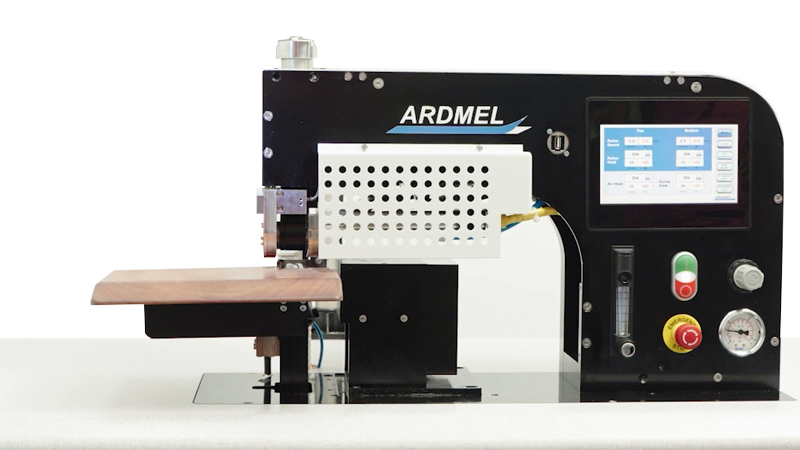

MK-975.01 Laydown Machine

Our MK-975.01 Laydown Machine is designed for hem laydown, waistband laydown, leg laydown, side seam laydown, and gusset laydown work.

Ideally suited for garments in activewear, outerwear and leisurewear, the MK-975.01 offers precision laydown ensuring accurate and consistent fabric placement, enhancing overall product quality. All while the high speed operation improves production efficiency with a fast and reliable laydown process.

Versatility is one of the MK975’s core strengths, being adaptable to various fabrics and elastic materials, providing flexibility in production. The user friendly interface comes with intuitive controls for easy operation and minimal training requirements.

Machine Features

• Adhesive lay down and edge trimming

• Fabric tape lay down and edge trimming

• Top Heated Rubber Roller

• Bottom-Heated Rubber Roller

• Top Hot Air Shoot

• Removable platform

• Attachable cutter unit

• Fixed position pre-heated tape guide

• Differential Speed

• Depth Stop

• Knee Press

• 7” HMI

• Auto power OFF option

• User log-in option