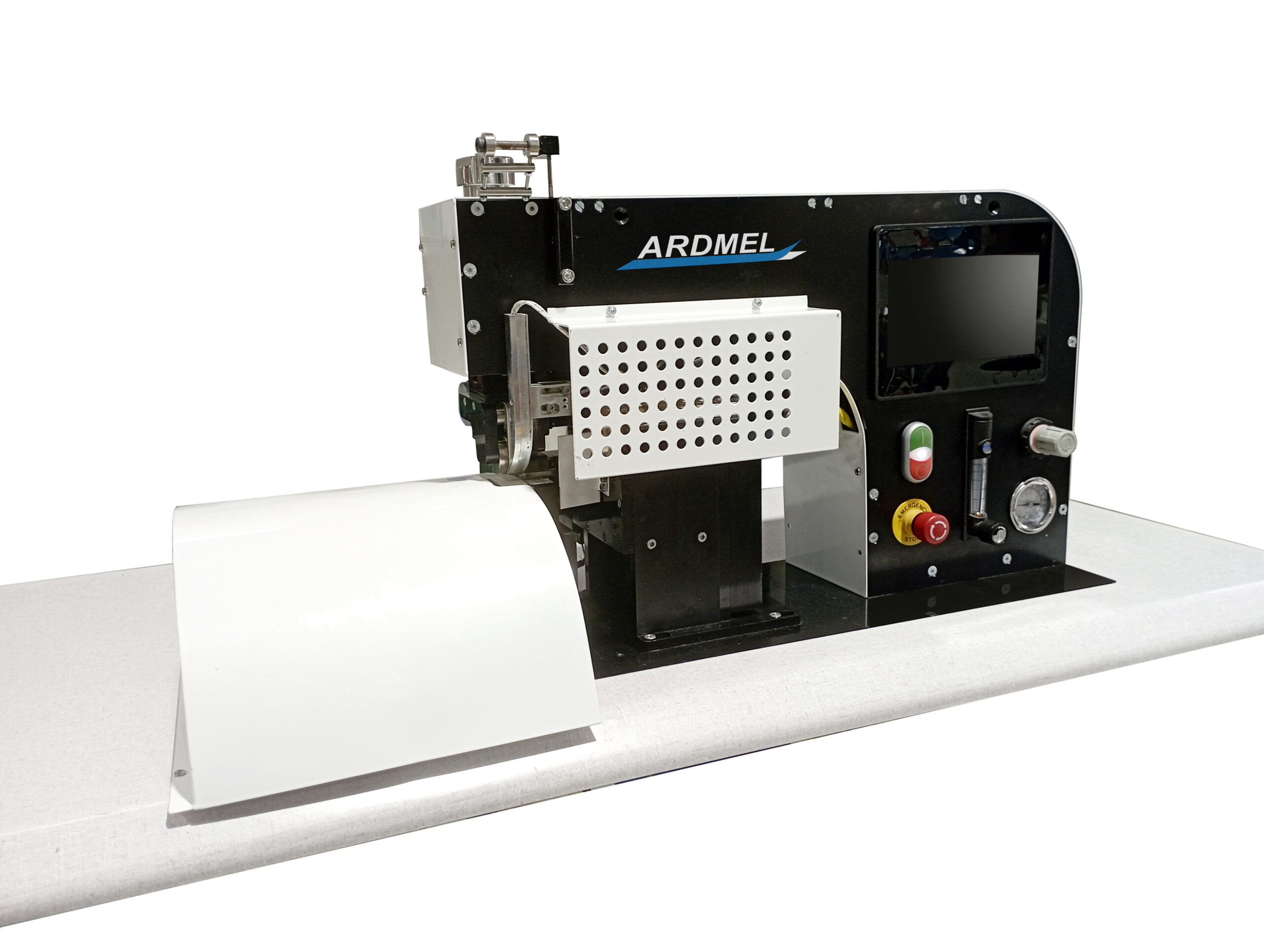

MK-975.02 Laydown Machine

The MK-975.02 Laydown Machine is engineered for precise laydown operations, including waistband, side seam, gusset, and other diverse applications.

This machine is ideally suited for garments in activewear, outerwear, and leisurewear, ensuring accurate and consistent fabric placement to enhance overall product quality. The high-speed operation of the MK-975.02 significantly improves production efficiency by delivering a fast and reliable laydown process. One of the core strengths of the MK-975.02 is its versatility, as it is adaptable to various fabrics and elastic materials, providing exceptional flexibility in production.

Machine Features

• Hot Air Shoot

◦ Use: Directs hot air precisely onto the fabric.

◦ Benefit: Enhances bonding quality and ensures strong, secure seams.

• Removable Platform

◦ Use: Provides flexibility in handling various garment sizes and types.

◦ Benefit: Facilitates easy adaptation for different laydown operations.

• Attachable Cutter Unit

◦ Use: Allows for integrated cutting during the laydown process.

◦ Benefit: Streamlines operations, saving time and improving efficiency.

• Preheated Tape Guide

◦ Use: Preheats tape before application.

◦ Benefit: Ensures better adhesion and consistent application of tape.

• Differential Speed

◦ Use: Adjusts the speed of different components to match fabric requirements.

◦ Benefit: Prevents stretching or puckering, ensuring smooth and accurate laydown.

• Top and Bottom Belt Gap Control (Depth-stop)

◦ Use: Controls the gap between top and bottom belts.

◦ Benefit: Ensures precise fabric placement and consistent laydown depth.

• Speed Control

◦ Use: Adjusts the operational speed of the machine.

◦ Benefit: Allows for customised speed settings to match fabric and production needs.

• Speed-Control Pedal

◦ Use: Provides foot-operated speed adjustment.

◦ Benefit: Enhances operator control and flexibility during the laydown process.

• 7” Touchscreen

◦ Use: Offers an intuitive interface for controlling machine settings.

◦ Benefit: Simplifies operation, improving user experience and efficiency.

• Auto Power OFF Option

◦ Use: Automatically powers off the machine after a period of inactivity.

◦ Benefit: Saves energy and enhances safety.

• User Logging Option

◦ Use: Tracks and logs user activity and settings.

◦ Benefit: Improves accountability and allows for performance monitoring.

• Convertible to MK975.03

◦ Use: Allows for upgrading to the MK975.03 model.

◦ Benefit: Provides future-proofing and scalability for evolving production needs.

Applications

• Sportswear & Outdoor Gear

• Medical

• Textile & apparel

• Intimates

Specification

• Maximum bonding temperature : 300 oC

• Maximum speed : 6 m/min

• Power requirements : 230 V AC 50 Hz single phase

• Compressed air : 80psi(min),120psi (max)

• Dimension : 1200mm X 800mm X 1500mm

• Weight : 90kg