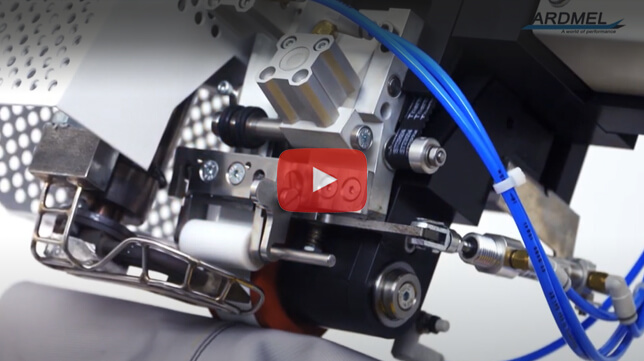

Mk501 Seam Sealer

The MK-501 seam sealer delivers operational ease, consistency, and uncompromising quality.

Equipped with a diverse array of attachments, this seam sealer offers heightened versatility to accommodate a range of applications. Seam sealers are versatile tools used in any application where creating durable, airtight, and waterproof seams is essential.

Energy Efficient

Energy Efficient

The MK-501 incorporates advanced technological features to optimise energy efficiency. Employing a 1800W heater, the system integrates an automatic energy-saving mechanism. This intelligent system conserves power and compressed air by executing a sequential shutdown process — first turning off the heater and, once cooled, deactivating the machine and its air supply.

Standard Fittings

Standard Fittings

| Automatic Scissors | Use: Streamlines the process of applying tape on seams during sealing operations Benefit: Enables seamless tape application and allows the operator to control tape feeding with incremental adjustments using the foot pedal |

|

| Dual Speed Knee Press | Use: Permits speed reduction for sealing cross-over seams on 3-layer materials, optimising control without interrupting the manufacturing process Benefit:Enhances efficiency by eliminating the need for separate hot stamping in these areas, streamlining the overall production workflow |

|

| Slack Feed Tape Device | Use: Allows unrestricted tape feed, reducing the risk of puckering and creasing in the sealed seams Benefit: Enhances the quality of the final product by ensuring smooth and even tape application without distortions |

|

| Nozzle Guard | Use: Includes an air cooled nozzle guard, eliminating the necessity for the operator to wear gloves, and helps prevent fabric scorching Benefit: Enhances operator comfort and safety, promoting a more ergonomic and user-friendly working environment |

|

| Depth Top Cylinder | Use: Facilitates the accommodation of thicker materials, such as neoprene, whilst also giving a flat finish on stretch and thinner fabrics. Benefit: Expands the versatility of the machine, enabling the effective sealing of a broader range of materials, thus enhancing the system’s adaptability. Additionally, it can regulate demarcation caused by pressure. |

|

| HMI Touchscreen | Use: Input data through the touchscreen HMI panel designed for easy programming. Benefit: Simplifies user interaction and programming, ensuring user-friendly operation and efficient machine setup. |

Optional Extras

Optional Extras

Binding Folder: Facilitates easy application of binding for underwear and sportswear.

Hemming Guide: Streamlines folding for hemming and lap seaming, suitable for underwear, sportswear, and outerwear.

50mm Reflective Kit: Simplifies the application of wider retro-reflective tapes, ideal for workwear and outerwear.

35mm Kit: Designed for applying wider tapes, up to 32mm in width.

Cylinder Arm: Enables easy tape application on sleeves and legs, tailored for workwear and outerwear.

Slim Quill: Eases tape application around tight corners.

Boot Quill: Facilitates tape application around acute curves, perfect for boots or gloves

Heated Top and Bottom Rollers: Enhances tape application on delicate fabrics with heated rollers.

Up/Down Adjustable Table: Allows easy height adjustment for versatile application scenarios.

SPECIFICATION

SPECIFICATION

Machine Details |

|

|---|---|

| Maximum Welding Temperature | - 750°C |

| Speed | - 11 m/min |

| Power Requirements | - 230 V AC 50 Hz single phase or 110 V AC 60 Hz |

| Compressed Air | - 142l/min, 90 psi (min), 120 psi (max), 5 CFM, 6.2-8.2 Bar, 152l/min |

| Bed Dimensions | - 1200mm x 600mm |

| Roller Width | - 28mm (standard) |

| Weight | - 147 kg (net) |

| Packed Dimensions | - 1350mm x 740mm x 1580mm |

| Packed Weight | - 251kg (gross) |

Energy Efficient

Energy Efficient