Close

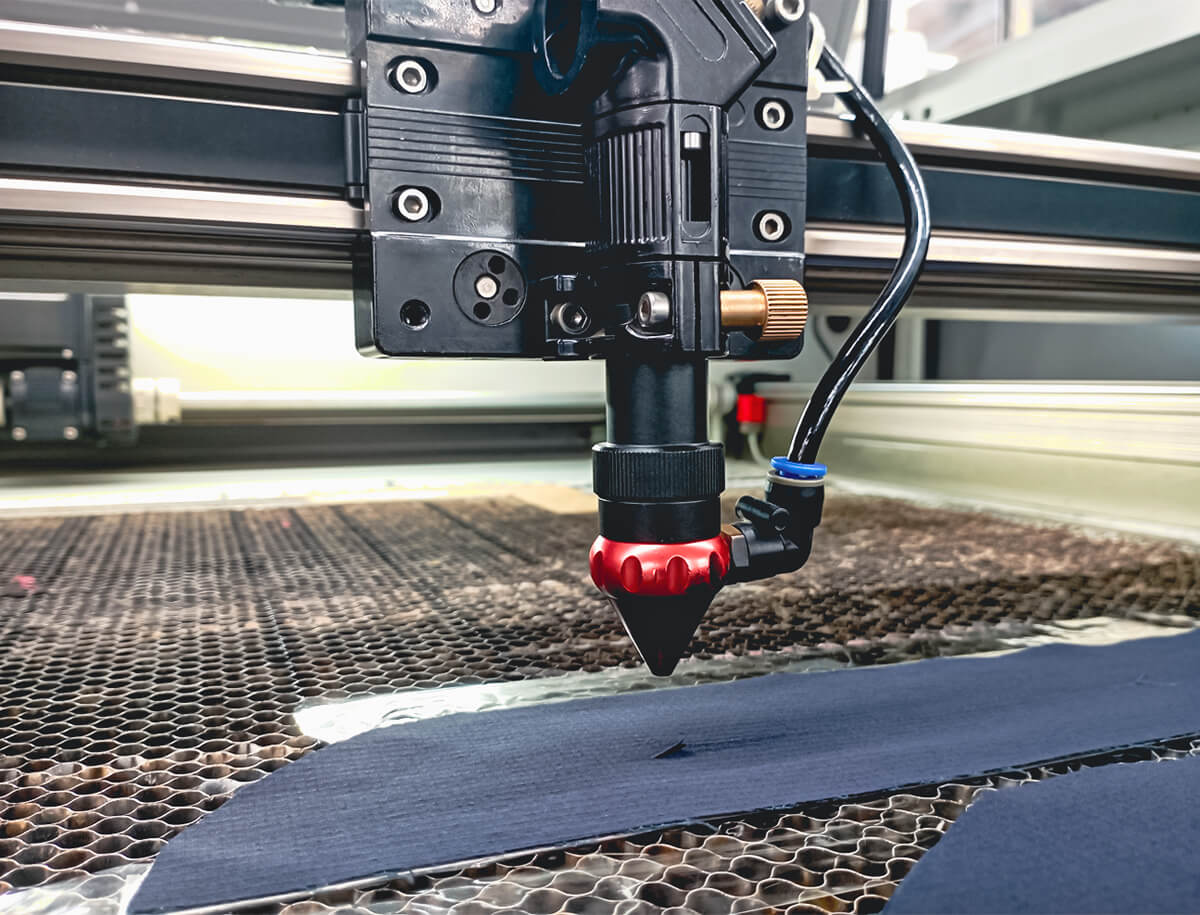

The LS950 is the next step in our quest for precision garment cutting and marking using laser technology. The LS950 provides millimetre accurate cutting and marking for garments with minimal fabric wastage – truly another step forwards for companies looking to minimise wastage in all areas of production.

The LS950 Laser and Engraving Machine provides high performance and flexibility on a variety of materials. With cutting speeds of up to 1000 mm/s, our laser cutter can provide a quality solution for your production needs at an affordable price.

Laser cutting is accurate and clean and safe.

• Cutting speeds up to 500mm/sec to an accuracy of 0.05mm.

• User friendly touch panel interface.

• X ,Y auto calibration option.

• Cutting smooth curves.

• The water cooling system cools the laser tube to increase the lifespan and performance of the laser tube.

• Customisable double laser head.

• Belt mesh customisable according to application requirement.

• Ability to read and edit different file formats such as PDF, AI, BMP, DXF, PLT, DST, JPEG & PNG giving the freedom to work with different software such as Adobe Illustrator, Adobe Photoshop, Auto CAD, Lectra, Gerber etc.

• Cutting route optimisation enables minimum changeover times between cuts.

• Layer processing order gives the ability to change the cutting sequence on an operation.

• Array, rotate, mirror, offset, object dimension and invert features.

• Ability to simulate the cut or the engraving on the software without doing the actual operation

• Freedom to use multiple layers enabling different power settings for different areas of the same work piece.

• Easy manipulation of machine maximum output power, speed, cutting origin and machine operation mode (cutting or engraving)

• Patterns can be previewed prior to cutting on the touch display

• Repeat cuts with automatic feeding

• Cutting garment markers quickly and accurately for sample production or small order quantities. Quick changes can be made and cut efficiently compared to traditional methods or paper plotting layering and cutting. Laser cut edges doesn’t fray.

• Cutting pattern boards for various production needs. Ex: Pattern sew jigs, placing boards, zipper opening.

• Cutting adhesives, gaskets, patches in bonded garments.

• Sticker cutting of patterns in cast films.

| Power Requirements | 230 V AC 50 Hz single phase 13 Amps |

| Compressed Air | 6 bar 1.5-2 cfm |

| Laser Type | CO2 Laser Tube |

| Maximum Output Power | 100W, 150W, 220W |

| Working Dimensions | 1600mm x 1000mm |

| - With Inkmarker | 1500mm x 1000mm |

| - With Glue Applicator | 1500mm x 1000mm |

| Dimensions | 2415mm x 2340mm |

• Sorting Area

• Smart edge alignment feeder

• Ink marker unit

• Glue applicator unit

• Camera

• Projector

| 100W | 150W | |

|---|---|---|

| Acrylic | 18mm | 25mm |

| MDF | 6mm | 10mm |

| Wood | 15mm | 18mm |

| Double Colour Board | 8mm | 10mm |

| Rubber | 5mm | 7mm |

| Leather | 7mm | 10mm |

| Cloth | 7mm | 10mm |

| Paper | 8mm | 10mm |

T: +44(0)1592 771 241

F: +44(0)1592 771 071

E: [email protected]