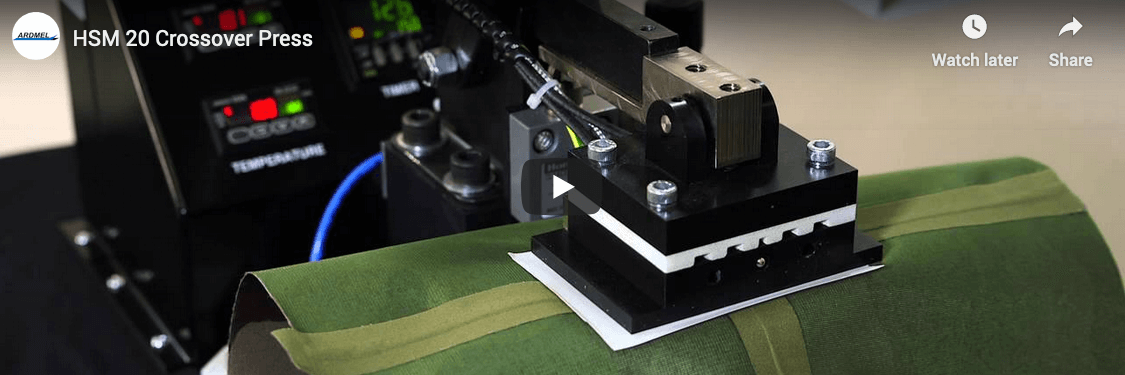

HSM-20 High Pressure Hot Stamp

Ideal for badge application, sealing embroideries, and cross-over seams

The HSM-20 Hot Stamp integrates with our range of solvent-free adhesives. Compatible with uncoated, coated, and laminated fabrics, it ensures superior adhesion, a soft handle for improved tactile experience, and enhanced strength.

We can also provide a selection of customised plates and foam pads, allowing the Hot Stamp to be tailored to your specific requirements. This ensures the production of the highest quality finished products tailored to your unique needs.

Machine Features

• Pressure Distribution

◦ Use: Engineered with membrane technology for a stable pressure distribution.

◦ Benefit: Ensures consistent and even pressure during operations, enhancing overall quality.

• Independent Plate Heating

◦ Use: Top and bottom heated plates can be operated independently.

◦ Benefit: Provides flexibility in managing different aspects of the process, optimising control and customisation.

• Simple Control Panel

◦ Use: Preset controls on an intuitive panel.

◦ Benefit: Enhances user-friendliness, ensuring ease of operation and precise outcomes.

• Dual Display Countdown Timer

◦ Use: Features a countdown timer with dual displays.

◦ Benefit: Allows users to monitor and manage the timing process more efficiently for accurate results.

• Differential Speed

◦ Use: Adjusts the speed of different components to match fabric requirements.

◦ Benefit: Prevents stretching or puckering, ensuring smooth and accurate laydown.

• Precise Controls

◦ Use: Comprehensive controls for timing, pressure, and temperature.

◦ Benefit: Offers precise adjustments, ensuring suitability for various materials and applications.

• Self-Levelling Bottom

◦ Use: Incorporates a self-levelling mechanism.

◦ Benefit: Automatically adjusts to substrate surfaces, ensuring uniform contact and preventing inconsistencies in the process.

Applications

• Textile & Apparel

• Automotive

• Branding & Customisation

OPERATION

OPERATION

| - The temperature and time are set and the machine is allowed to reach temperature |

| - The fabric/seam if placed on the bottom plate |

| - The handle is pulled to clamp the Hot plate down onto the fabric/seam, which starts the timer |

| - After the set time an audible warning is given and the handle is pushed back, releasing the fabric/seam |

SPECIFICATION

SPECIFICATION

Machine Details |

|

|---|---|

| Maximum Temperature | - 350°C |

| Maximum Dwell Time | - 999.9 seconds |

| Minimum Dwell Time | - 0.0 seconds |

| Hot Plate Standard Size | - 150mm x 100mm – optional size 75mm x 63mm We can also create a personalised hot stamp tailored to your specific requirements |

| Height of Bottom Plate | - 128mm |

| Supply Voltage | - 230V |

| Current Consumption | - 5.5 Amps |