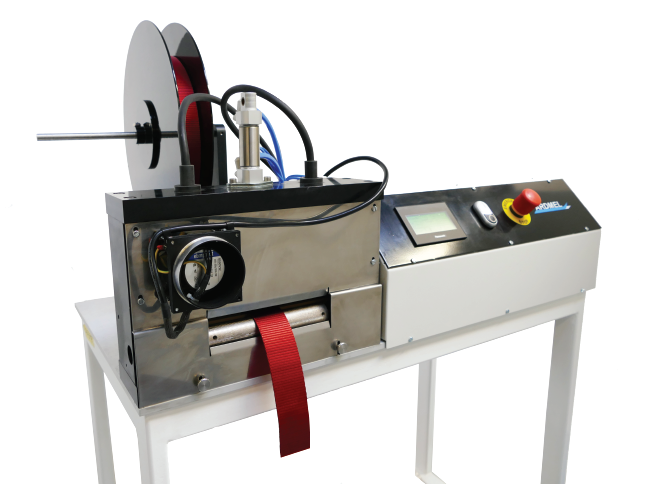

SC-200i HMI Strip Cutting Machine

Enhancing operational efficiency through the implementation of automated processes

Presenting a standalone, resilient, and industrially robust strip cutter system. This heavy-duty unit is engineered to proficiently tackle the most demanding strip cutting tasks. It excels in precision cutting for a diverse range of materials, including webbing, elastics, cords, cuffing, and more, ensuring efficiency and accuracy.

The sophisticated drive and control module accommodates three cutting modules: Cold guillotine, Straight hot knife and Angled hot knife. Employing pneumatic drive mechanisms, these modules offer prolonged service life with minimal maintenance requirements, presenting an optimal balance of durability and ease of operational adaptability.

APPLICATIONS

APPLICATIONS

| - Seatbelts |

| - Webbing |

| - Zippers |

| - Hook & loop |

| - Cords and ropes |

| - Ribbons and labels |

| - Coated fabrics |

| - Rubbers |

| - Felts |

| - Tapes |

| - Tubing |

Standard Features

Standard Features

• Automatic Settings

◦ Use: Allows precise control over length, quantity, temperature and dwell time, enabling unmanned operation.

◦ Benefit: Minimises wastage, as the machine automatically stops once the desired quantity is reached, optimising efficiency.

• Multi Feed

◦ Use: Capable of cutting multiple rolls simultaneously, up to 6” (152mm) wide, with an optional attachment for up to 9” (228mm). Spring-clamped top and bottom drive rollers prevent slippage.

◦ Benefit: Enhances versatility by efficiently handling multiple material feeds simultaneously, optimising output in a single operation.

• Soft Start

◦ Use: Incorporates a soft start motor function to prevent excessive fabric tension at the process’s initiation.

◦ Benefit: Reduces the risk of slippage or over-stretching, maintaining material integrity and quality throughout the cutting process.

• High Accuracy

◦ Use: Achieves exceptional cutting accuracy within ± 1mm over a maximum length of 65 metres.

◦ Benefit: Ensures precision in cutting, meeting stringent quality standards and minimising material wastage.

• Feed Speed

◦ Use: Operates at a maximum feed speed of 36 meters/min, with an inch speed of 5 meters/min for loading.

◦ Benefit: Balances efficiency and control, allowing for swift processing while ensuring careful loading to prevent damage.

• HMI Touchscreen

◦ Use: Input data through the touchscreen HMI panel designed for easy programming.

◦ Benefit: Simplifies user interaction and programming, ensuring user-friendly operation and efficient machine setup.

OPTIONAL EXTRAS

OPTIONAL EXTRAS

| Heavy Duty Hot Knife | |

| Heavy Duty Cold Guillotine Knife | |

| Angle Hot Knife | |

| Pneumatic Marker System | - Marks webbing where the operator is required to sew |

| Slack Feed Unit | - Feeds webbing into strip cutter, stopping webbing from slipping |

| Mechanical End Detector | - Detects the end of the webbing |

SPECIFICATION

SPECIFICATION

Machine Details |

|

|---|---|

| Power Requirements | - 230 V AC 50 Hz single phase 10 Amps |

| Pneumatic | - 7 bar at 6 litres/minute |

| Feed Block Width (Standard) | - 6 inch (150mm) |

| Feed Block Width (Optional) | - 9 inch (228mm) |

| Maximum Feed Length | - 99,999mm in 1mm increments |

| Maximum Feed Speed | - 36 metres per minute |

| Dimensions | - 930mm x 500mm x 1200mm |