What is the Difference Between Flashing Tape and Seam Tape?

At Ardmel Automation, we understand the importance of using the right materials to ensure durability and protection in construction and manufacturing. One common area of confusion is the difference between flashing tape and seam tape. While both are used for sealing purposes, they serve distinct functions and are designed for different applications. Selecting the right tape can significantly impact the performance and longevity of a structure, whether in roofing, insulation, or industrial processes.

This article explores the key differences between flashing tape and seam sealing tape, covering their material composition, usage, and best practices for application.

What is a Flashing Tape?

Flashing tape is a highly durable adhesive tape that creates a waterproof barrier in construction and industrial applications. It typically uses butyl rubber, acrylic adhesive, or rubberised asphalt, offering superior resistance to moisture and environmental conditions.

People primarily use flashing tape to prevent water ingress in areas prone to leaks, such as around window and door openings, roof joints, and cladding connections. It directs water away from vulnerable areas, ensuring the integrity of the building envelope.

What is a Seam Tape?

Seam tape, also known as seam sealing tape, joins and seals two surfaces to prevent air and moisture infiltration. Made from polyethene, polypropylene, or other synthetic materials, it features a strong adhesive backing that bonds securely to surfaces.

People widely apply seam tapes in construction, insulation, and manufacturing, especially to seal joints in house wraps, vapour barriers, subfloors, and industrial materials. Unlike flashing tape, which waterproofs the exterior, seam tape creates airtight and watertight seals within structures.

What is the Difference Between Flashing Tape and Seam Tape?

The primary distinction between flashing tape and seam tape lies in their function. Flashing tape is engineered for moisture protection in high-risk areas, while seam tape is used to join and seal materials.

Other key differences include:

Material Composition: Flashing tape is thicker and more robust, often reinforced for weather resistance, whereas seam tapes are typically thinner for easy application over joints.

Adhesive Properties: Flashing tape adhesives are formulated to withstand extreme weather and movement, while seam sealing tapes provide strong adhesion for static joints.

Flexibility and Application: Flashing tape is highly flexible to accommodate expansion and contraction, making it ideal for external applications. Seam tapes are designed for internal use where flexibility is less critical.

seam sealing tape

Waterproofing Capabilities

Flashing tape is specifically designed to prevent direct water penetration, making it essential for external applications such as roof flashing, window sealing, and facade protection. It creates a continuous barrier against rain, snow, and humidity.

While seam tapes also offer moisture resistance, their primary function is to seal overlaps in membranes and vapour barriers, preventing condensation and air leakage rather than direct exposure to water.

Application Techniques

For optimal performance, proper application of both flashing tape and seam sealing tape is crucial:

Flashing Tape Application: Surfaces must be clean, dry, and free from dust to ensure maximum adhesion. Overlapping edges correctly and pressing the tape firmly into place enhances durability.

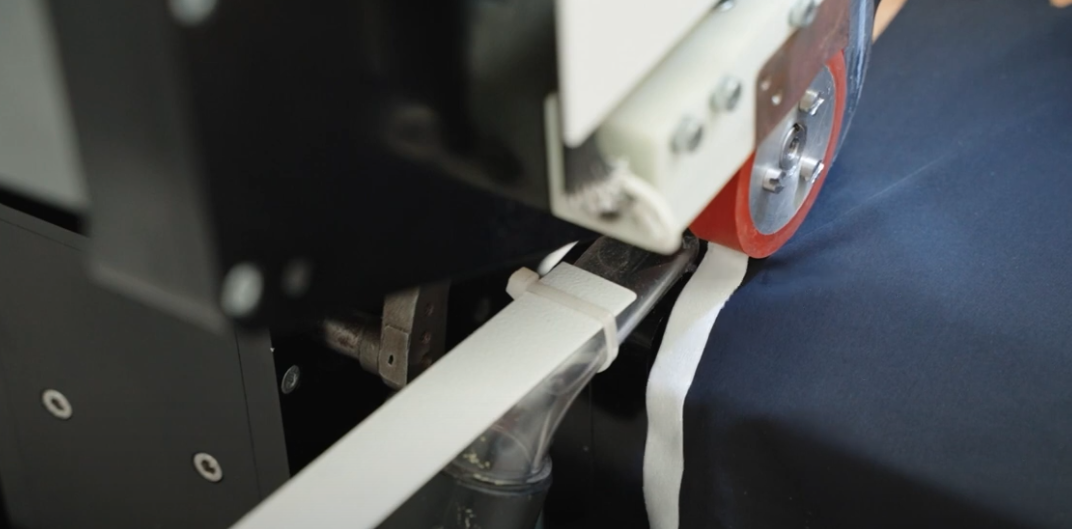

Seam Tape Application: Seam tape is generally easier to apply and is used on large-scale projects such as sealing insulation panels, house wraps, and industrial packaging. Rolling the tape firmly onto the surface ensures a tight, long-lasting bond.

Suitability for Different Climates and Environments

Climate conditions significantly affect the performance of seam tapes and flashing tapes.

Flashing Tape Performance: Designed to endure extreme temperatures, UV exposure, and moisture, flashing tape is suitable for external applications in diverse weather conditions.

Seam Tape Performance: Best suited for internal applications, seam tapes work effectively in controlled environments such as within walls, flooring systems, and insulation layers.

Cost and Budget Considerations

Flashing tape is generally more expensive due to its enhanced durability and weatherproofing capabilities. However, it provides long-term protection, reducing the risk of water damage and costly repairs.

Seam tape is a cost-effective solution for projects requiring airtight and watertight joints, making it an economical choice for large-scale applications such as house wraps and vapour barriers.

Common Mistakes and How to Avoid Them

Some common errors when using seam sealing tape and flashing tape include:

Improper Surface Preparation: Dust, moisture, or debris can compromise adhesion, leading to failures.

Incorrect Overlapping: Insufficient overlap can create weak points, allowing air or moisture to penetrate.

Using the Wrong Tape: Choosing seam tape for applications that require flashing tape (or vice versa) can result in suboptimal performance.

Following manufacturer guidelines and selecting the right tape for the specific application ensures maximum durability and effectiveness.

Wrapping Up…

Understanding the differences between flashing tape and seam tape is essential for ensuring optimal sealing, moisture protection, and long-term durability in construction and industrial applications.

Flashing tape is specifically designed for external moisture defence, preventing water ingress in roofing, cladding, and window installations.

Seam tapes, including seam sealing tape, are used to join materials securely, creating airtight and watertight seals in house wraps, vapour barriers, and insulation systems.

At Ardeml Automation, we provide high-quality seam sealing tapes designed for superior adhesion and long-lasting performance. Whether you need industrial-grade seam tape or specialist sealing solutions, our products ensure efficiency, reliability, and durability.

Looking for premium seam sealing tapes? Contact us today to find the right solution for your project.