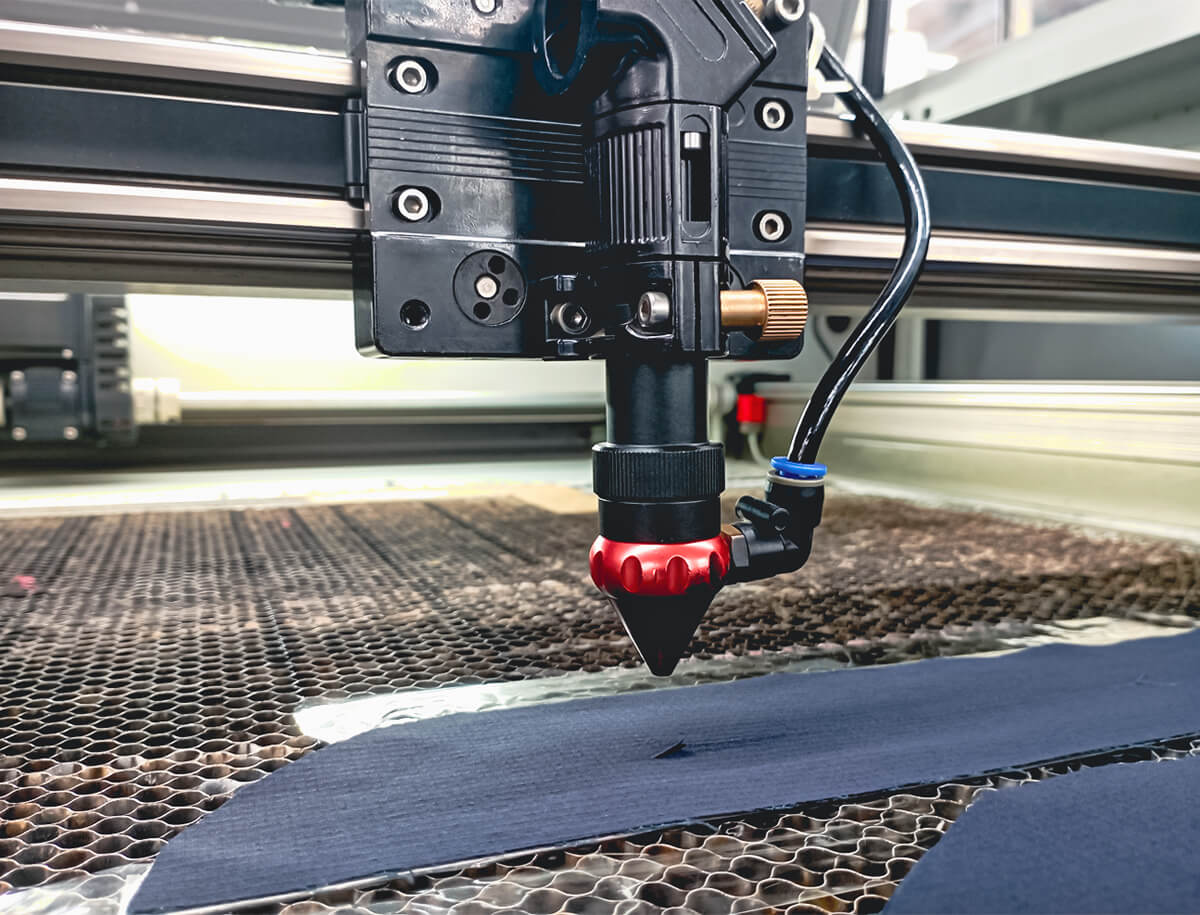

LS550 Laser Machine

Perfect for fabric marking and cutting.

Providing millimetre accurate cutting and marking for garments with minimal fabric wastage – the LS550 truly is another step forwards for companies looking to minimise wastage in all areas of production.

The LS550 Laser and Engraving Machine provides high performance and flexibility on a variety of materials. With cutting speeds of up to 500 mm/s, our laser cutter can provide a quality solution for your production needs at an affordable price.

Laser cutting is accurate, clean and safe.

Machine Features

• Cutting speeds up to 500mm/s with precise dimensional accuracy

◦ Use: Achieves rapid and precise cutting with minimal margin of error.

◦ Benefit: Enhances productivity and ensures high-quality results, even for intricate designs and fine details.

• Water cooling system with laser operation

◦ Use: Cools the laser tube to maintain optimal operating temperature and prevent overheating.

◦ Benefit: Prolongs the lifespan of the laser tube, ensuring consistent performance and minimising downtime due to potential damage.

• User friendly touch panel interface

◦ Use: Pre-set controls on an intuitive panel.

◦ Benefit: Enhances user-friendliness, ensuring ease of operation and precise outcomes.

Software

• Versatile File Compatibility: Capable of reading and editing various file formats such as AU, BMP, DXF, PLT, DST, JPEG and PNG ensuring compatibility with popular design software like Adobe Illustrator, Adobe Photoshop, AutoCAD, Lectra and Gerber.

• Optimised Cutting Routes: Enables cutting route optimisation, minimising changeover times between cuts for enhanced operational efficiency.

• Flexible Layer Processing: Allows adjustment of the cutting sequence for different layers during operation, enhancing flexibility and customisation.

• Comprehensive Editing Tools: Includes array, rotate, mirror, offset, object dimension, and invert capabilities for precise design adjustments and customisation.

• Simulation Capability: Enables simulation of cutting or engraving processes within the software interface, allowing users to preview and optimise designs before actual operation.

• Layered Power Settings: Supports multiple layers with individual power settings for fine-tuning laser parameters, enhancing control and versatility.

• Preview Functionality: Allows previewing of patterns directly on the touch display before cutting, facilitating visualisation and verification of designs.

Application Examples in the Textile Industry

• Cutting pattern boards for various production needs. Ex: Pattern sew jigs, placing boards, zipper opening.

• Cutting adhesives, gaskets, patches in bonded garments.

• Sticker cutting of patterns in cast films.

Specification

| Power Requirements | 230 V AC 50 Hz single phase 13 Amps |

| Laser Type | CO2 Laser Tube |

| Maximum Output Power | 150W |

| Working Dimensions | 1000mm x 600mm |

| - With Inkmarker | 900mm x 600mm |

| Dimensions | 1120mm x 1630mm |

Optional Units/Features

• Smart edge alignment feeder

• Ink marker unit

• Glue applicator unit

• Fixed or moveable camera

• Projector