Close

At Ardmel, our creative division is all about working with you to take your concept all the way to a workable end solution. How do we do that? Below you can see the step by step process on how we will guide you through the stages, to take your idea from a concept on a drawing board to a final end product and the realisation of a dream into reality.

As experts in a range of fields within engineering and manufacturing, whether you’re working with a new fabric or looking for bespoke machinery, we’re well placed to help you identify any pitfalls that may be waiting for you, and how to realise your ideas to their highest potential.

Ardmel CREATE – with you in mind.

When you first contact us we’ll go through with you a number of questions, ensuring we have a full view of where you currently are, what resources you have available, what you want to achieve, and why.

If you’re not 100% sure what you need, don’t panic! Just let us know as much as possible and we will work with you to build the outline of what is required.

We’ll keep in close contact with you throughout the process and updating you on the results; we’re always available to answer your questions or tweak the process if there are changes to your requirements.

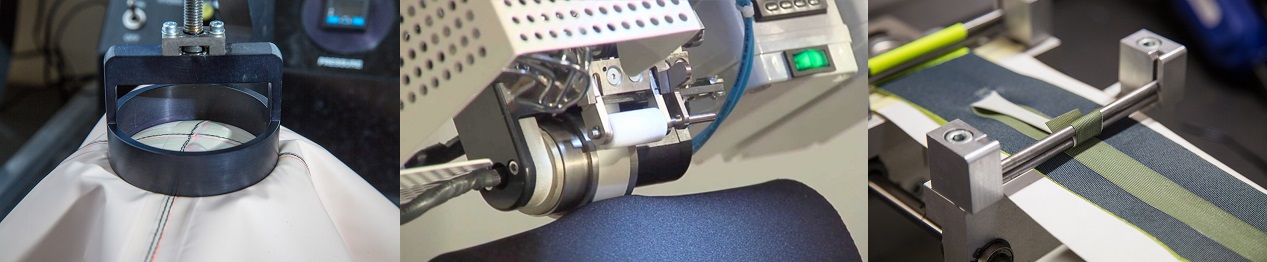

When working with your materials we will ask you to send us samples; we will then use these for our preliminary testing, which allows us to understand better the qualities of your materials and what will work best with them.

Each material has its own unique set of conditions which lead to the best bonding and adhesion, and the same is true for machinery of every type. Being able to see a sample of what you are working with allows us to immediately rule out any inappropriate avenues, and concentrate on those which will work best for you.

We’ll combine the outcome of our inspection of your materials with the information we gathered from you to come up with some ideas for how best to create what you need.

We will narrow down the options to those most viable, and our team will then go through the various options with you, noting the advantages and disadvantages of each. If required you can take multiple options through to the next stage or alterations can be made and a new set of options given according to new requirements.

Using the options you have approved, we’ll create samples for you to see and touch.

This can include showing you a taped seam using your fabric and our recommended tape and settings, or any other output which you would find useful and which would help you to make a final decision.

Before your choice is fully approved we’ll undertake a range of testing, to ensure that your chosen option performs just as well once fully assembled.

With our variety of in-house testing machines we are able to make sure our solution meets all of your requirements and will continue to perform.

Once everything is confirmed, our expert team will ensure you have all of the information you need to be successful; this can include specific material information and machine settings.

As well as being available through phone and email, if required our team are also able to travel out to your premises to provide in-depth training and assistance.

The cycle will then begin anew as we will remain in touch with you and available for any required support, as well as future development.

T: +44(0)1592 771 241

F: +44(0)1592 771 071

E: [email protected]