What Are the Methods of Fabric Testing?

In the world of textile manufacturing, ensuring your fabrics and seams perform as required is no longer optional. At Ardmel Automation, we understand that seam performance, water-resistance, and overall fabric integrity go hand in hand. Whether you’re applying seam sealing tapes, running seam sealing machines or investing in fabric testing equipment, it’s critical to understand how fabric testing works and why it matters.

In this article we’ll explore the key methods of fabric testing, including the use of fabric testing machines and the specialised hydrostatic head tester, and connect them to how you select the right seam sealing tapes for waterproof seams.

Why fabric testing matters (and how it ties to seam sealing)?

When you apply a high-performance product like waterproof seam sealing tape, you need to be sure the fabric it attaches to will behave reliably: the fabric needs to resist tearing, abrasion, seam slippage, water ingress, and degradation over time. The testing of fabric sets the foundation for success: you’re not just applying a tape or running a seam sealing machine; you’re ensuring the substrate is up to spec.

For example:

If you use heavy duty fabric sealing tape or waterproof seam sealing tape but the fabric fails a burst or abrasion test, then the seam will be the weakest link. On the other hand, knowing that your fabric passed specific mechanical and physical tests means you can have confidence in your seam sealing strategy, whether you’re using a seam sealing machine or hand-applying seam sealing tapes for fabric.

Additionally, for industries like outdoor gear or waterproof clothing, a test like the hydrostatic head tester is indispensable to quantify how much water pressure the fabric (and seam) can withstand.

By aligning your fabric testing protocols with your seam sealing strategy, you move from simply “applying a tape” to ensuring a fully integrated waterproof solution. That’s the value Ardmel Automation brings, not just the tape, but the full system.

Fabric Testing: Key Categories of Methods

Fabric testing broadly falls into three major categories. Understanding these helps you decide which tests your fabrics should undergo and how your seam-sealing strategy intersects with them.

Physical Testing:

Physical testing focuses on the basic physical characteristics of a textile sample: weight (GSM), thickness, fabric count, fibre length, stiffness, coatings, and so forth.

Examples:

- GSM (grams per square metre) measurement

- Fabric thickness / density

- Fabric count in woven structures

Why this matters for seam sealing:

If the fabric is too light, too thin, or insufficiently robust, even the best seam tape waterproof product might delaminate or fold under pressure. Knowing your substrate’s physical baseline helps you select the right seam sealing tape for fabric and adjust application parameters in your seam sealing machines accordingly.

Mechanical Testing:

Mechanical testing examines how the fabric behaves under forces: stretching, breaking, tearing, abrasion, slippage of seams, fatigue.

Key mechanical tests are:

- Tensile strength / grab test: how much force before the fabric or seam breaks.

- Tear strength: how easily it rips under a given test setup.

- Seam slippage: how the fabric behaves around a sewn seam when load is applied.

- Abrasion resistance: how the fabric surface holds up to rubbing/fretting.

For a fabric intended to be used with seam sealing tape, mechanical testing is critical: you need the fabric not only to hold the tape but to perform reliably under conditions (movement, flexing, tension) that the end product will face.

Chemical & Performance Testing:

This category deals with how fabric performs when exposed to chemical agents, light, heat, water, and other environmental stresses. It also includes safety tests for harmful substances.

Typical tests:

- Color fastness to light, washing, rubbing

- Water resistance / water repellency (see below under hydrostatic head)

- Chemical composition, harmful substances

- Flammability

When using fabric sealing tape or a fabric seam sealer, you must ensure compatibility: for instance, the tape adhesive must not degrade under required chemical/temperature exposures or cause fabric discoloration. Having the results from performance/chemical testing gives you confidence in your seam sealing strategy.

Spotlight: The Hydrostatic Head Tester

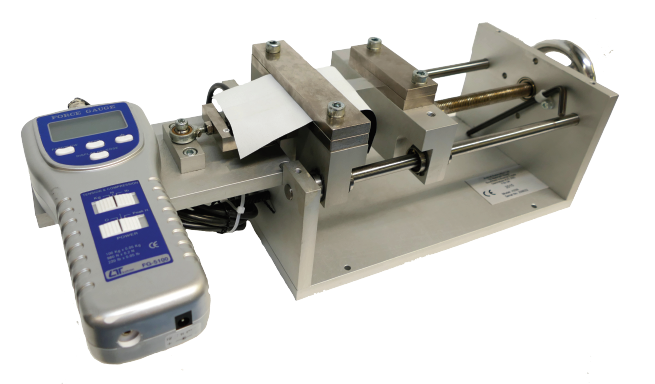

One of the most important machines in the world of waterproof fabrics and sealed seams is the hydrostatic head tester, a type of machine under the broader category of textile testing equipment.

In fact, when fabric is used in waterproof clothing, tents, geotextiles or protective gear, the hydrostatic head value indicates how much water column pressure the fabric (and by extension the seam + tape) can resist before leaking.

What it does:

A hydrostatic head tester applies water pressure (a column of water) to fabric clamped in a chamber until water penetration occurs. The height of the water column at failure is reported (often in mm or m). Machines labelled “‐ Auto Hydrostatic Pressure Tester” fall under this category.

Why it matters for seam sealing?

- It quantifies water resistance of the fabric itself.

- But when combined with your seam and the seam sealing tape or seam sealing machine process, you can gauge the waterproof performance of the finished product (fabric + seam + tape).

- If fabric fails at a low hydrostatic head, no amount of tape will fully compensate. Conversely, if fabric passes but the seam fails, you know to improve the seam sealing method (better tape, better machine, better application).

- In specification sheets for outdoor garments, you’ll often see terms like “Hydrostatic head 10,000 mm” – a measure that the client or OEM will look for.

How it integrates with fabric testing machines?

When you audit your substrate, you will likely use a suite of fabric testing machines, including tensile testers, abrasion testers, air-permeability testers, and the hydrostatic head tester.

From the results, you can assess:

- “Is the fabric robust enough for my application?”

- “What are the weakest points (seams, adhesive interface, etc)?”

- “What level of seam sealing tape specification do I need?”

- “What seam sealing machine (automated or manual) will deliver the required performance?”

- By doing so, you move from reactive (“leaks occurred”) to proactive (“we specify fabric + tape + machine based on test data”).

Selecting Fabric Testing Machines: A Practical Guide

When your facility or QA lab is investing in testing equipment, or when you are working with a partner like Ardmel Automation, here are practical things to consider.

The machines you should prioritise:

- Universal tensile/strength machine (for fabrics, seams, composites).

- Abrasion/pilling testers.

- Air-permeability testers, thickness gauges, GSM/weight cutters.

- Hydrostatic head tester / auto hydrostatic pressure testers.

- Seam fatigue testers (less common but relevant if you’re doing seam sealing tape application testing).

- Textile Notes

Integration with seam sealing processes:

- Ensure your seam sealing machines can interface with your QA results: e.g., if your hydrostatic head test shows fabric passes 10,000 mm but seams only 6,000 mm, invest in better seam sealing tapes or refine machine calibration.

- Use test machines to validate new seam tape waterproof products: for example, apply the tape across seam and test a sample under hydrostatic head or burst to verify performance.

- Use mechanical test results (tensile/tear) to determine which seam sealing tape for fabric is best: heavy-duty fabrics may require stronger adhesive or wider tape.

- Document and publish your test results to build trust with customers: “Fabric passed 12,000 mm hydrostatic head when sealed with our heavy duty seam sealing tape”.

Buying tips:

- Make sure the testing machines comply with international standards (ASTM International, International Organization for Standardisation) which makes your results credible.

- Look for digital interfaces, data logging and software support to link results with your manufacturing/sealing lines.

- For seam sealing lines, consider tolerance, repeatability, and how results link back to your choice of seam sealing tapes, seam sealing machines, and fabric substrates.

Seam Sealing Tapes & Seam Sealing Machines: The Link to Fabric Testing

Now that we’ve covered fabric testing methods and machines, let’s bring this back to your core interest: selecting and validating seam sealing tapes (also known as seam tape), and integrating them into your production via seam sealing machines.

Why test the fabric before tape selection?

- If you go straight to choosing a tape without knowing substrate performance you risk mismatches:

- A lightweight fabric may delaminate even though the tape would perform well on heavier fabrics.

- A fabric that fails hydrostatic head test at low pressure means even the best waterproof seam tape cannot meet premium specs.

- A fabric with low tear/abrasion resistance may damage the tape interface over time, reducing waterproofness.

Thus, the flow becomes: fabric testing, select suitable tape, apply via seam sealing machine, validate finished product.

How to choose seam sealing tape variants?

Consider your fabric and application:

- For general waterproof garments: choose “waterproof seam sealing tape” or “seam tape for clothing” that meets the fabric’s hydrostatic head rating and abrasion profile.

- For heavy duty applications (workwear, tents, outdoor gear): you may need “heavy duty seam sealing tape” with a more aggressive adhesive or larger width.

- For UK market or exports: you might specify “waterproof seam sealing tape UK” to ensure compliance with regional standards.

- Ensure the tape is compatible with your sealing machine (thermal, ultrasonic, adhesive) and with the fabric type (woven, knitted, laminated).

Application via seam sealing machines:

A reliable seam sealing machine ensures uniform application of the tape, consistent heat/pressure (for heat-sealable tapes), and aligned with seam lines. Combined with solid QA from your fabric testing machines, you’ll produce a seam that matches the design specification.

Ardmel Automation offers both the tape (seam sealing tapes) and the equipment (seam sealing machines) so you benefit from a holistic approach: We help you choose the right tape based on your fabric test data, integrate it with machine settings, and validate the final product for waterproofness and endurance.

Why Choose Ardmel Automation for Your Seam Sealing & Testing Needs?

At Ardmel Automation, we are uniquely positioned to provide:

- A wide range of seam sealing tapes including “best seam sealing tapes”, “fabric sealing tape”, “heavy duty seam sealing tape”, “waterproof seam sealing tape ”.

- Seam sealing machines and automation solutions for consistent, high-quality application of tapes onto you fabric substrates.

- Advice and support on fabric testing machines and integration of testing results into your sealing workflow.

- A one-stop solution: assessment of your fabric, recommendation of appropriate tape, machine setup, and final validation testing.

So if you’ve got fabric that needs to be sealed, waterproofed and tested to perform reliably, Ardmel Automation delivers the full value chain.

Ready to elevate your fabric performance?

Contact Ardmel Automation today to discuss your fabric substrate, testing results and sealing requirements. Let’s work together to select the right seam sealing tapes, set-up your seam sealing machines, and ensure your final product passes the required tests, whether for waterproof outdoor gear, technical garments, or industrial textiles.

Call us now or request a quote to get started on improving your seam sealing and fabric testing workflow.