What Is a Tensometer and Why Is It Critical for Testing Seam Sealing Tape Performance?

In technical textile manufacturing, waterproofing is only half the equation. The real challenge lies in ensuring that sealed seams can withstand mechanical stress, repeated movement, and real-world usage. This is where the tensometer, one of the most critical fabric testing machines, becomes indispensable.

While seam sealing tapes prevent water penetration, their effectiveness must be measured, validated, and standardised. A tensometer allows manufacturers to quantify seam strength, peel resistance, elongation, and failure points, ensuring that seam sealing processes meet performance and compliance requirements.

At Ardmel Automation, we support manufacturers with seam sealing tapes, seam sealing machines, and fabric testing solutions, helping them achieve consistent, test-proven results.

This guide answers the most important questions manufacturers ask about tensometers, their role in fabric and seam testing, and how they directly impact waterproof seam performance.

What Is a Tensometer in Fabric Testing?

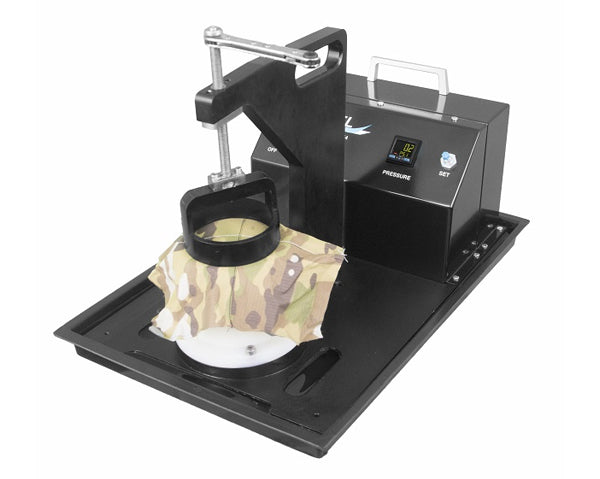

A tensometer is a textile testing machine used to measure the tensile strength and elongation properties of fabrics, seams, and bonded materials. It applies a controlled pulling force to a sample until it stretches or breaks, capturing precise performance data.

In seam sealing applications, tensometers are used to test:

- Seam strength after seam sealing

- Adhesion quality of seam sealing tape

- Peel resistance of waterproof seam tape

- Fabric deformation under load

- Failure mode (fabric tear vs tape delamination)

Unlike visual inspections, a tensometer provides quantifiable, repeatable results, making it essential for quality assurance and R&D.

Why Is Tensometer Testing Essential for Seam Sealing Tapes?

Seam sealing tapes are exposed to constant stress during wear, washing, and environmental exposure. Without proper testing, manufacturers risk:

- Seam delamination

- Tape peeling under tension

- Fabric tearing at the seam

- Waterproof failure in real-world use

A tensometer ensures that fabric seam sealing tapes perform as intended, even under extreme conditions.

Key benefits include:

- Verifying compatibility between fabric and seam tape

- Optimising seam sealing machine settings

- Reducing product returns and warranty claims

- Ensuring compliance with ISO and ASTM standards

This is especially critical when working with waterproof seam sealing tape, heavy duty seam sealing tape, or seam tape for clothing and PPE.

How Does a Tensometer Test Seam Sealed Fabrics?

A tensometer test follows a controlled and standardised procedure:

- Sample Preparation: Fabric samples are stitched and sealed using seam sealing machines with the selected seam sealing tape.

- Clamping the Sample: The fabric is mounted in the tensometer grips, ensuring uniform alignment.

- Applying Tensile Load: The machine applies a gradual pulling force at a defined speed.

- Data Collection: The tensometer records force, elongation, and displacement in real time.

This data is crucial for selecting the best seam sealing tapes for specific fabric constructions.

What Seam Sealing Tape Properties Can a Tensometer Measure?

A tensometer evaluates several critical properties of seam sealing tapes:

- Tensile Strength: Measures how much force a seam can withstand before failure.

- Peel Strength: Assesses how strongly the seam sealing tape adheres to the fabric surface.

- Elongation at Break: Determines how much the seam stretches before breaking—important for flexible garments.

- Seam Slippage: Identifies fabric movement at the seam under load.

How Does Tensometer Testing Improve Waterproof Performance?

While hydrostatic head testers measure water resistance, tensometers ensure structural integrity. A seam may pass waterproof tests initially but fail under tension. Tensometer testing prevents this by:

- Identifying weak seam constructions

- Validating adhesive activation parameters

- Ensuring long-term seam durability

For manufacturers producing waterproof garments, tensometer + hydrostatic head tester combinations offer complete performance validation.

Why Is Tensometer Testing Important for Seam Sealing Machine Optimisation?

Incorrect seam sealing machine settings can cause:

- Under-bonding of seam sealing tape

- Overheating and fabric damage

- Poor tape adhesion

- Inconsistent seam strength

By testing samples on a tensometer, manufacturers can fine-tune:

- Temperature

- Pressure

- Speed

- Tape selection

This ensures repeatable, production-ready results.

Which Industries Rely Most on Tensometer Testing?

Tensometer testing is critical across multiple sectors:

- Outdoor and sportswear

- PPE and safety garments

- Medical textiles

- Military and tactical gear

- Industrial fabrics

In all these industries, seam sealing tapes must perform under load, not just in lab conditions.

How Does Tensometer Testing Support Compliance and Certification?

Many international standards require tensile testing, including:

- ISO textile standards

- ASTM seam strength tests

- EN standards for protective clothing

Using a tensometer allows manufacturers to:

- Document compliance

- Support certification audits

- Meet buyer and regulatory expectations

How Ardmel Automation Supports Seam Sealing and Fabric Testing?

At Ardmel Automation, we offer a complete ecosystem:

- Seam sealing tapes

- Seam sealing machines

- Fabric testing machines including tensometers

- Technical guidance and application support

Our solutions help manufacturers:

- Select the right seam tape

- Validate seam strength

- Improve waterproof performance

- Reduce production risk

Final Thoughts: Why Tensometer Testing Is Non-Negotiable

In modern textile manufacturing, performance must be proven, not assumed. A tensometer provides the data-driven assurance that seam sealing tapes will hold under real-world conditions.

When combined with the right seam sealing tapes and seam sealing machines, tensometer testing becomes the foundation of reliable, waterproof fabric production.

Ready to Validate Your Seam Performance?

Talk to Ardmel Automation today to explore tensometers, seam sealing tapes, and fabric testing machines tailored to your production needs.