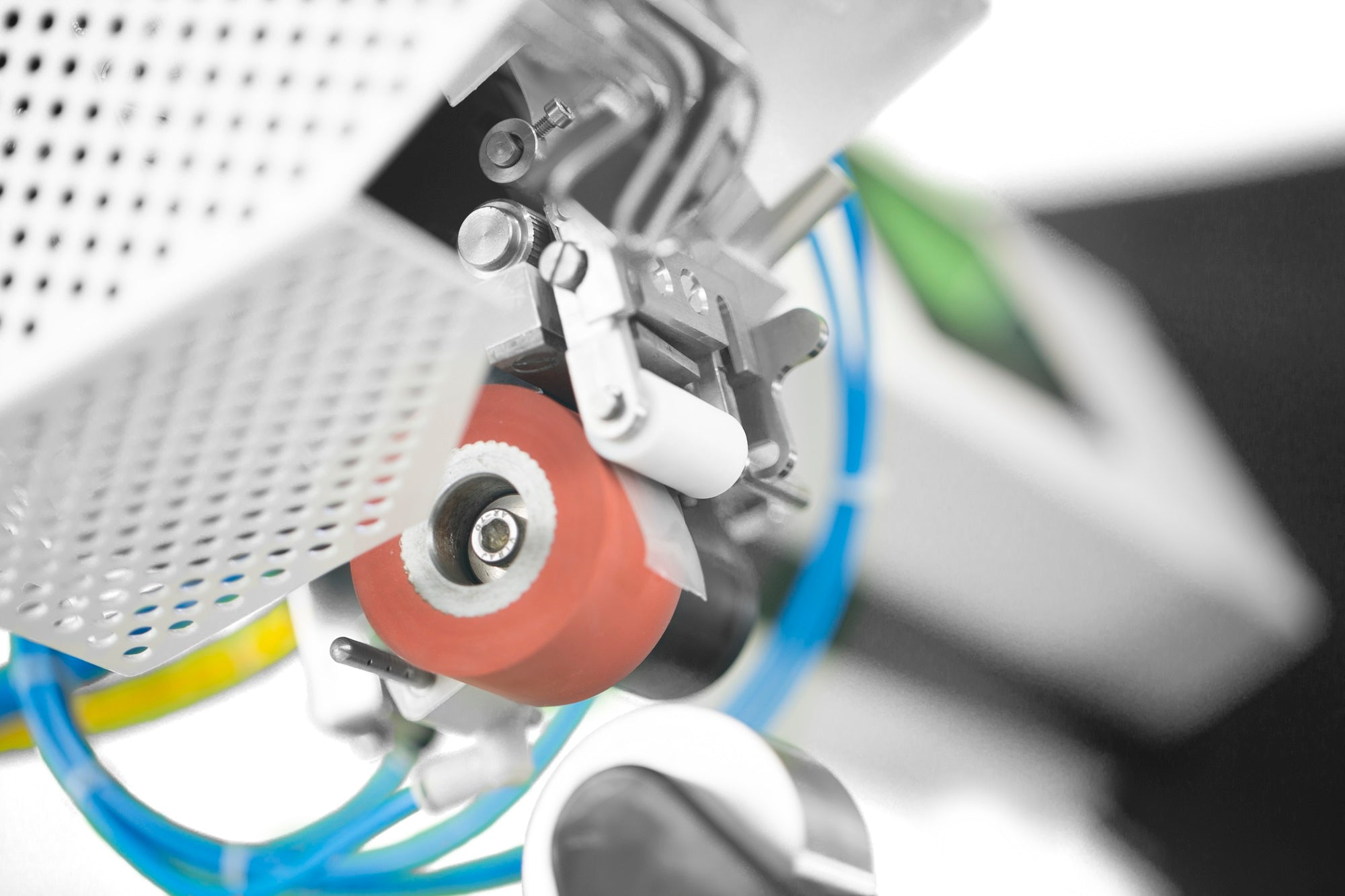

The MK-10i sealer delivers operational ease, consistency, and uncompromising quality. Equipped with a diverse array of attachments, this seam sealer is highly versatile and can accommodate a range of applications.

A seam sealer is a versatile tool for use in any application where creating durable, airtight, and waterproof seams is essential. Featuring a user-friendly touch-screen, adjustments can be made quickly and easily.

Energy Efficient & Eco Processes

Ideal for badge application, sealing embroideries, and cross-over seams

Specification

Max Weld Temp: 750°C

Speed: 18m/min

Power Requirements: 230 V AC 50 Hz single phase, or 110 V AC 60 Hz

Compressed Air Requirements: 6 Bar (100-137psi) @ 152 l/min (4 CFM)

Machine Dimensions: 1200mm x 600mm

Roller Width: 28mm (standard)

Weight: 147kg

Choose options

Take your production to the next level

New Features

Differential Feed

The MK-10i includes a differential feed, which is particularly beneficial in industries and applications where the machine needs to handle different types of fabrics, materials, or multiple layers simultaneously.

Features

Automatic Tape Feeding

Use: Streamlines the process of applying tape on seams during sealing operations

Benefit: Enables seamless tape application and allows the operator to control tape feeding with incremental adjustments using the foot pedal

Dual Speed Knee Press

Use: Permits speed reduction for sealing cross-over seams on 3-layer materials, optimising control without interrupting the manufacturing process

Benefit: Enhances efficiency by eliminating the need for separate hot stamping in these areas, streamlining the overall production workflow

Depth Stop Cylinder

Use: Facilitates the accommodation of thicker materials, such as neoprene, whilst also giving a flat finish on stretch and thinner fabrics.

Benefit: Expands the versatility of the machine, enabling the effective sealing of a broader range of materials, thus enhancing the system’s adaptability. Additionally, it can regulate demarcation caused by pressure.

Air Cooled Nozzle Guard

Use: Includes an air cooled nozzle guard, eliminating the necessity for the operator to wear gloves, and helps prevent fabric scorching

Benefit: Enhances operator comfort and protection, improves safety and promotes a more ergonomic and user-friendly working environment

Auto Scissor

Use: Eliminates manual tape cutting during seam sealing

Benefit: Enhances operator efficiency and ensures smooth production flow

Get extra functionality with our

Optional Attachments

Our optional attachments give greater versatility, allowing you to create a machine that meets your specific requirements. We are also able to provide fully bespoke customisations - if you don’t see what you need below, let our team know and they can assist.

Binding Folder

Facilitates easy application of binding for underwear and sportswear

Hemming Guide

Streamlines folding for hemming and lap seaming, suitable for underwear, sportswear, and outerwear

Reflective Kit

Available in 35mm or 50mm, it simplifies the application of wider retro-reflective tapes, ideal for workwear and outerwear

Boot Quill

Facilitates tape application around acute curves, perfect for boots or gloves

Cylinder Arm

Enables easy tape application on sleeves and legs, tailored for workwear and outerwear

Heated Top and Bottom Rollers

Enhances tape application on delicate fabrics with heated rollers

Slim Quill

Eases tape application around tight corners

Up/Down Adjustable Table

Allows easy height adjustment for versatile application scenarios

Slack Feed Tape Device

Ensures smooth and even tape applications without distortions

Need help?

Frequently Asked Questions

No! Our expert team work with many customers helping them take their initial idea through to a final product.

Yes, we can ship to many global destinations, and have agents available to help you with the details.

Yes, we manufacture a wide range of consumables for many different specialisms - our team can work with you to identify the one which will work best for you