SMS-600 Ultrasonic Sewing Machine

Innovating design concepts through the application of stitch-less technology.

Ultrasonic sewing machines are versatile tools used in various industries for a range of applications due to their ability to bond materials without the need for traditional stitching.

Advantages Over Conventional Stitches

- Provides a totally watertight seam

- Seams are less bulky with no edge fraying

- Uses small seam allowances to create flatter seams

- Improves comfort on next-to-skin garments

- Cleaner cosmetic appearance

Power Requirements: 230 V AC 60 Hz single phase

Pneumatic: 6 bar at 60 litres/minute

Dimensions: 1200mm x 540mm x 1100mm

Weight: 130kg (net)

Packed Dimensions: 1310mm x 680mm x 1290mm

Packed Weight: 225kg (gross)

Choose options

The SMS-600 Ultrasonic Sewing Machine by Ardmel represents a unique approach to ultrasonic technology, offering threadless bonding of textiles.

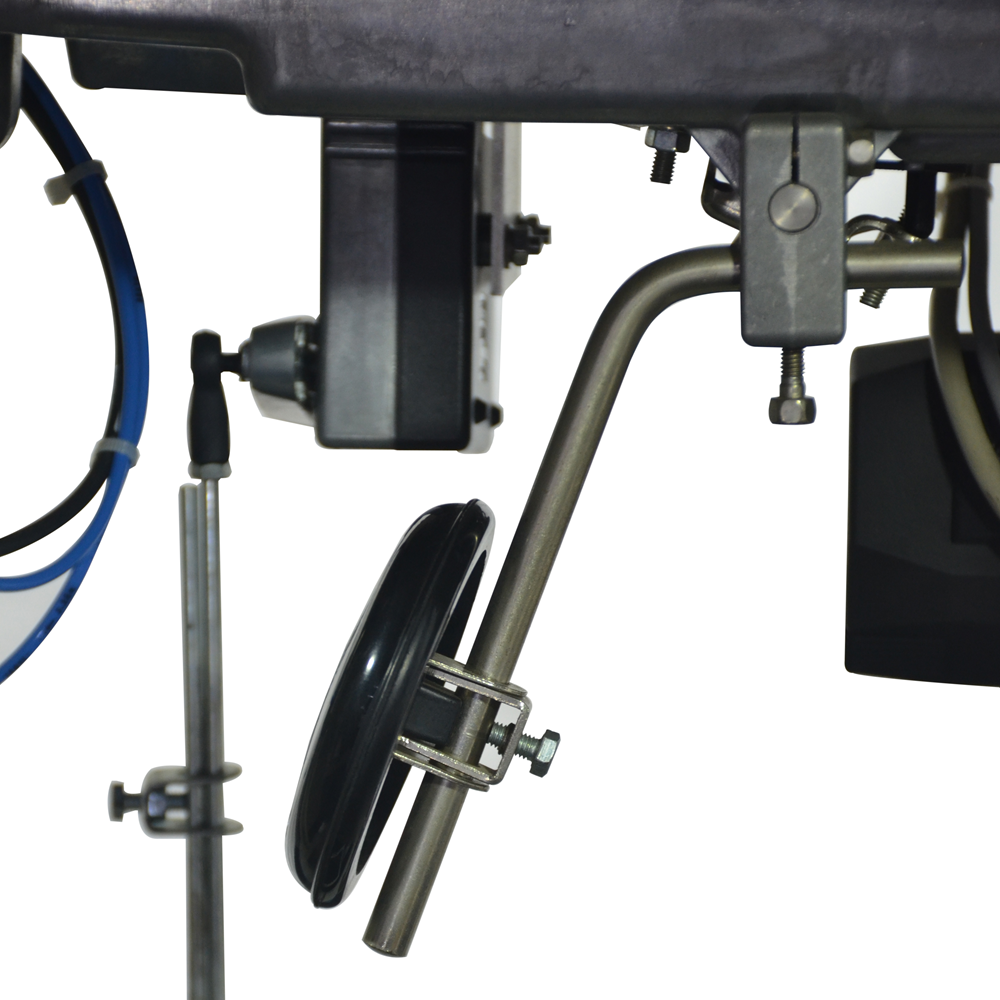

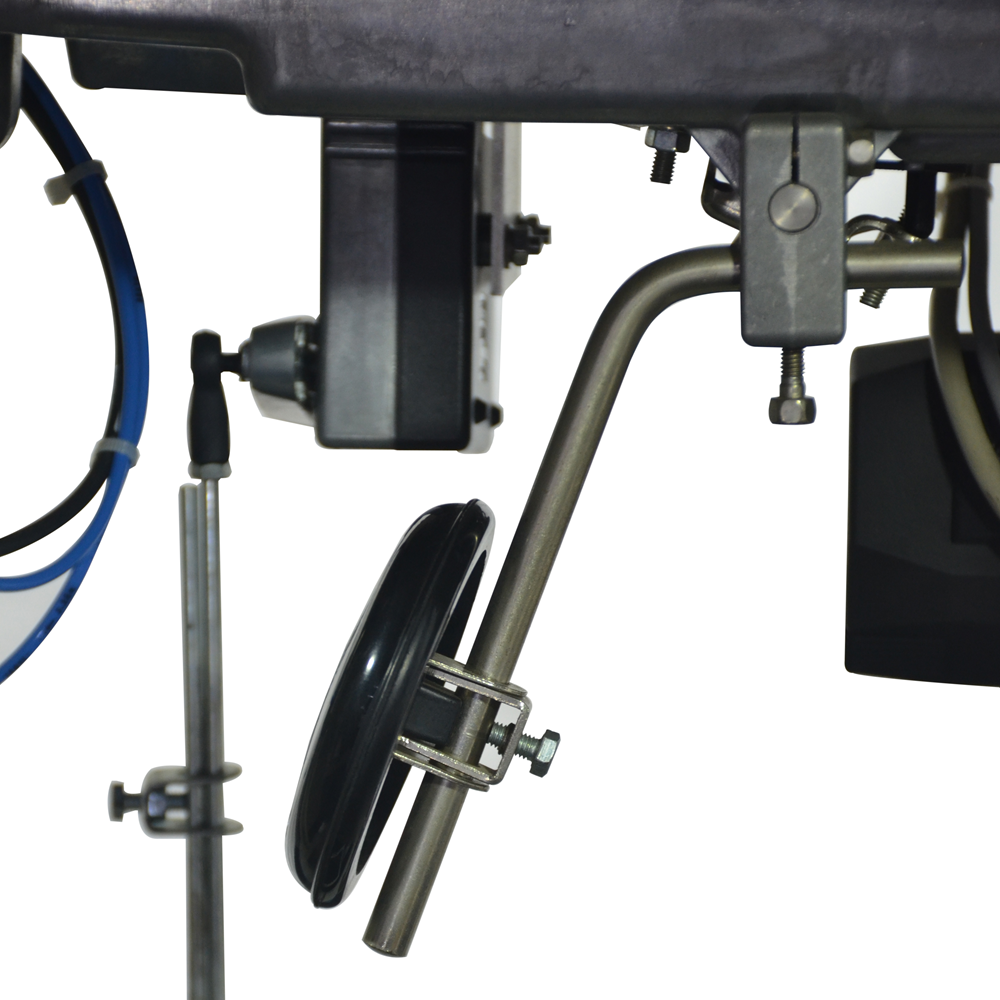

Distinguished by its unique design, this machine ensures ease of manipulation around curves. The SMS-600 can handle a variety of different fabrics, delivering smooth threadless seams, that can be strengthened further by tape application to the exterior or underside.

Designed with physical resemblance to a traditional sewing machine, the SMS-600 minimises additional training requirements, ensuring operators swiftly attain proficiency in its operation.

This machine incorporates advanced technological features to optimise energy efficiency. With an integrated automatic energy-saving mechanism, this intelligent system conserves power and compressed air by deactivating the air supply when not in use.

Features

35kHz Generator

Use: Delivers high-frequency ultrasonic energy for precision bonding.

Benefit: Swiss craftsmanship ensures reliability and efficiency in ultrasonic technology.

CE Marked – Noise Reduction

Use: Minimises ultrasonic generator noise to prevent hearing damage.

Benefit: Compliance with CE marking standards promotes user safety and workplace health.

Microprocessor Control

Use: Regulates and optimises the ultrasonic sewing process.

Benefit: Enhances precision and consistency in seam quality through advanced control mechanisms.

HMI Touchscreen

Use: Input data through the touchscreen HMI panel designed for easy programming.

Benefit: Simplifies user interaction and programming, ensuring user-friendly operation and efficient machine setup.

Watertight Seams

Use: Ensures seam integrity and water resistance in finished products.

Benefit: Ideal for applications requiring waterproof or water resistant properties.

Less Bulky Seams

Use: Creates smoother, less bulky seams for improved aesthetics.

Benefit: Enhances the visual appeal of finished products, meeting high cosmetic standards.

See the SMS-600 in Action

Need help?

Frequently Asked Questions

No! Our expert team work with many customers helping them take their initial idea through to a final product.

Yes, we can ship to many global destinations, and have agents available to help you with the details.

Yes, we manufacture a wide range of consumables for many different specialisms - our team can work with you to identify the one which will work best for you