What Is an Auto Seam Sealer?

An auto seam sealer is a specialised adhesive material used in the automotive industry to seal joints, seams, and gaps on vehicle bodies. These car seam sealing tapes prevent water, dust, and corrosion from entering areas where metal panels or parts meet, ensuring long-term durability and protection.

At Ardmel Automation, we design and manufacture advanced seam sealing machines and automotive seam sealing tapes trusted by professionals worldwide. Our seam sealing technology combines efficiency, precision, and reliability, qualities essential for modern automotive production (Society of Motor Manufacturers and Traders [SMMT], 2024).

Why Seam Sealing Is Essential in Automotive Manufacturing?

Seam sealing is a critical process in both vehicle assembly and repair. It protects the car body by:

- Preventing water ingress and corrosion in weld joints or seams.

- Enhancing sound insulation and reducing cabin noise.

- Improving aerodynamic efficiency by smoothing surface transitions.

- Extending vehicle lifespan while maintaining aesthetics.

Without proper seam sealing, moisture and salt can penetrate joints, leading to rust, paint blistering, and structural weakening, particularly in climates prone to heavy rain or road salt, such as the UK (Automotive Manufacturing Solutions, 2023).

What Types of Sealants Are Used on a Vehicle?

Different sections of a vehicle require different sealants. Here are the most common types used in automotive seam sealing:

Polyurethane Seam Sealers:

- Commonly used for bonding and sealing car panels.

- Strong adhesion, flexibility, and paintable surfaces.

- Ideal for car body seam sealer applications.

Epoxy Seam Sealers:

- Used where high durability and temperature resistance are required.

- Common in automotive seam sealing for structural joints.

Acrylic Sealers:

- Cost-effective and fast-drying.

- Often used for interior car panels or low-stress joints.

Butyl and Rubber-Based Sealers:

With superior waterproofing and elasticity, these sealers are common in doors, trunks, and window seams (British Standards Institution [BSI], 2023).

Car Seam Sealing Tapes:

- A modern, efficient alternative to traditional liquid sealants.

- Provide consistent coverage and reduced mess.

- Compatible with automated seam sealing machines for faster production.

Ardmel’s car seam sealing tapes are engineered to deliver strong adhesion, temperature resistance, and durability, ideal for automotive seam sealing applications in both manufacturing and repair settings.

How to Seam Seal a Car?

Seam sealing can be performed manually or with automated seam sealing machines. Here’s how the process works:

-

Surface Preparation:

Thoroughly clean the surface to remove dirt, grease, or oxidation. Proper preparation ensures maximum adhesion of the car seam sealing tapes. -

Applying the Seam Sealer or Tape:

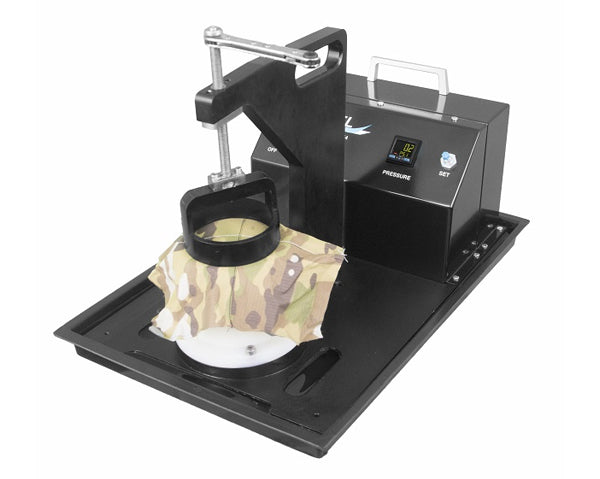

In manual processes, a car body seam sealer is applied using a brush or caulking gun. In automated setups, seam sealing machines use heat and pressure to bond automotive seam sealing tapes precisely along panel joints. (Automotive Manufacturing Solutions, 2023). -

Smoothing the Seal:

A roller or spatula ensures even coverage and a clean finish. -

Curing and Inspection:

After application, the sealer must cure to reach full strength. Ardmel’s heat-activated seam sealing tapes bond instantly, allowing faster production without sacrificing durability.

Advantages of Car Seam Sealing Tapes over Liquid Sealers

Unlike traditional liquid sealers, car seam sealing tapes deliver:

- Cleaner, faster application.

- Uniform thickness for consistent protection.

- Strong temperature and weather resistance.

- Reduced material waste.

- Immediate readiness for painting or finishing.

These benefits make automotive seam sealing tapes ideal for high-volume manufacturers, repair shops, and restoration specialists seeking improved productivity and quality (SMMT, 2024).

Ardmel Automation: Leaders in Seam Sealing Technology

With decades of expertise in automation and bonding technology, Ardmel provides advanced seam sealing machines and car seam sealing tapes across diverse industries, including:

- Automotive manufacturing

- Outdoor and performance wear

- Medical textiles

- Protective equipment

- Industrial fabrics

Our innovative sealing systems ensure precision and performance, whether you’re sealing a car door, an EV battery housing, or a high-performance jacket.

Why Choose Ardmel Seam Sealing Solutions?

- High Performance: Consistent sealing, even on complex shapes.

- Versatile Compatibility: Suitable for metals, composites, and plastics.

- Energy Efficient: Designed for low-temperature bonding and reduced waste.

- Customisable: Various widths, adhesives, and materials available.

- Proven Reliability: Trusted by automotive manufacturers worldwide.

When quality and precision matter, Ardmel’s automotive seam sealing solutions offer unmatched results.

The Future of Automotive Seam Sealing

As the industry transitions toward electric vehicles (EVs) and lightweight materials, the demand for advanced seam sealing technologies continues to grow. Automated systems using car body seam sealer tapes offer manufacturers:

- Improved production efficiency.

- Reduced manual labour.

- Consistent adhesion across composite surfaces.

- Compatibility with sustainable materials.

At Ardmel, we’re leading this innovation by supplying smart sealing machines that combine precision engineering with automation for the next generation of vehicle production.

Final Thoughts

Although often overlooked, auto seam sealing is vital for the longevity and safety of every vehicle. From preventing corrosion to enhancing structural durability, it ensures that every seam and joint performs flawlessly.

At Ardmel Automation, we’re proud to provide industry-leading car seam sealing tapes, automotive seam sealing machines, and custom automation solutions that set new standards for reliability and performance.

Contact Ardmel Automation today to discover how our sealing technologies can streamline your automotive production or repair process.

FAQs ( Frequently Asked Questions )

-

What’s the Best Seam Sealing Adhesive for Automobiles?

The best seam sealing adhesive depends on the application. For most OEM and repair uses, heat-activated car seam sealing tapes offer superior efficiency, cleanliness, and consistency. -

What Is the Difference Between Seam Sealing and Welding?

Welding joins metal surfaces permanently, while seam sealing protects those joints from corrosion, leaks, and noise. Both are essential for vehicle integrity

References

Automotive Manufacturing Solutions. (2023). Sealing technologies in automotive production. Retrieved from https://www.automotivemanufacturingsolutions.com

British Standards Institution. (2023). BS EN ISO 11600: Building construction – Jointing products – Classification and requirements for sealants. London, UK: BSI.

Society of Motor Manufacturers and Traders. (2024). UK automotive manufacturing guidelines and best practices. Retrieved from https://www.smmt.co.uk