What is a Seam Sealing Machine?

In today’s fast-paced manufacturing landscape, seam sealing machines are crucial for producing high-quality products that are both durable and waterproof. Whether you’re manufacturing waterproof jackets, tents, or personal protective equipment (PPE), a seam sealing machine seals every stitch with precision, blocking water, wind, and other elements from getting through. At Ardmel, we help you choose the right seam sealing machine to ensure tightly sealed seams and top-performing products that meet the highest standards.

In this blog, we’ll explore what a seam sealing machine is, the types available, their advantages and disadvantages, and how to choose the best machine for your production line. Whether you’re looking for machines to seal taped seams or you’re considering upgrading your current equipment, this guide will help you make an informed decision.

What Is a Seam Sealing Machine?

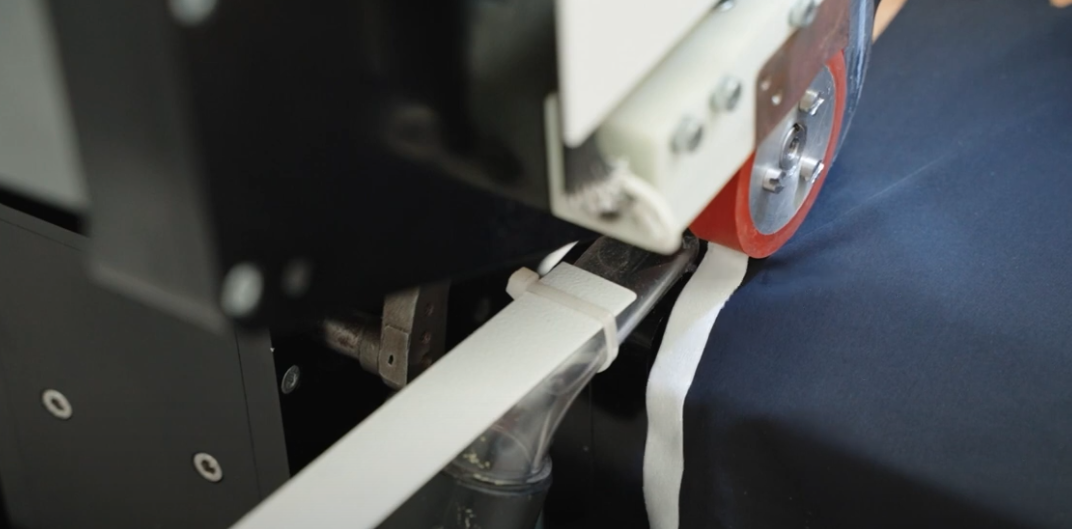

Operators use a seam sealing machine to apply seam sealing tapes over stitched seams in fabric and other materials. The goal of seam sealing is to create a waterproof or airtight barrier over the seam, which is often the weakest point in a product. Seam sealing machines use heat, pressure, or ultrasonic energy to bond the seam sealing tape to the fabric, making sure that no moisture can penetrate the material through the stitched seams.

These machines are essential in industries where waterproofing is a must, such as in the production of waterproof jackets, tents, safety wear, and even in automotive applications where sealing is necessary to protect critical components.

What Are the Types of Seam Sealing Machines?

There are several types of seam sealing machines, each designed for different types of materials, production needs, and sealing techniques. Understanding the various options will help you choose the most suitable machine for your operations.

Hot Air Seam Sealing Machines

A Hot Air Seam Sealing Machine uses precisely controlled streams of hot air to activate the adhesive on seam sealing tapes. The heat from the air melts the adhesive, bonding it to the fabric, creating a seamless, waterproof barrier. These machines are particularly effective for lightweight, synthetic fabrics, making them ideal for outdoor clothing like waterproof jackets and protective gear.

Example:

Imagine you’re producing a line of waterproof hiking jackets. The fabric you’re using is lightweight and breathable, but you need to ensure that no water seeps through the seams. A Hot Air Seam Sealing Machine would be the perfect choice for this, as it seals the seams effectively without damaging the delicate material.

Hot Wedge Seam Sealing Machines

Hot Wedge Seam Sealing Machines work by using a heated wedge to melt the adhesive on the seam sealing tape. The adhesive is then pressed onto the fabric with rollers, ensuring that the tape bonds securely to the fabric. This method is particularly useful for heavier materials that require higher heat to activate the adhesive.

Example:

For a company manufacturing heavy-duty PPE gear, such as protective suits or safety jackets, a Hot Wedge Seam Sealing Machine would be ideal. These garments often use thicker, more durable materials that need a more intense method to ensure the seams are sealed properly.

Ultrasonic Seam Sealing Machines

Ultrasonic Seam Sealing Machines use high-frequency ultrasonic vibrations to generate friction, producing heat that melts the adhesive and bonds the seam sealing tape to the fabric. This method is highly precise, making it perfect for fabrics that need clean, precise seams. Ultrasonic machines are also ideal for PPE seam sealing tapes, as they don’t require adhesives, reducing the potential for chemical contamination.

Example:

If you’re producing medical-grade PPE clothing such as face masks or protective gowns, Ultrasonic Seam Sealing Machines would be a great choice. They are clean, precise, and reduce the risk of contamination during the sealing process.

Why Are Sealing Machines Important?

Sealing machines play a pivotal role in ensuring that products meet their intended purpose, particularly when it comes to waterproofing and airtight sealing. Industries that require high-performance standards, such as outdoor apparel, construction, and healthcare, rely heavily on seam sealing machines to produce quality, reliable products. These machines ensure that taped seams are applied correctly, offering superior protection from environmental elements and contaminants.

By choosing the right seam sealing machine, businesses can improve product quality, boost production efficiency, and ensure that their products meet the rigorous demands of consumers and industries alike.

What Is the Purpose of a Seam Sealing Machine?

The main purpose of a seam sealing machine is to prevent water, air, or any other external elements from penetrating through the stitched seams of a product. By using seam sealing tapes, these machines ensure that the seams are properly sealed and protected. This is especially crucial in the production of waterproof or airtight products, such as outdoor clothing, tents, or protective gear.

For example, consider the production of a waterproof tent. The stitched seams are potential points where water can infiltrate, compromising the tent’s waterproof qualities. Using a seam sealing machine, the manufacturer can apply taped seams over these stitched areas, ensuring the tent remains waterproof even in heavy rain or adverse weather conditions.

Statistical Insight:

Experts estimate that global demand for waterproofing products in the apparel industry will grow by 7.1% annually, driven largely by advancements in seam sealing technology. A Technavio report projects that the global seam sealing machine market will grow by over 5% between 2021 and 2026, reflecting rising demand for efficient and reliable seam sealing solutions across industries such as outdoor apparel, construction, and medical equipment.

What Is an Example of a Seam Sealing Machine?

An example of a seam sealing machine that’s widely used in the industry is the JUKI L-8100 Series Hot Air Seam Sealing Machine. This high-performance machine uses hot air to apply seam sealing tapes to a wide range of fabrics, from lightweight synthetics used in waterproof jackets to heavier materials used in industrial PPE gear. The JUKI L-8100 ensures a consistent and reliable seal, ideal for high-volume production lines where both speed and accuracy are essential.

With its adjustable temperature controls, the JUKI L-8100 allows manufacturers to tailor the heat to specific materials, ensuring a secure bond between the fabric and seam sealing tape. This machine has proven popular in various industries, including apparel, outdoor gear, and medical protective equipment.

Statistical Insight:

According to a report from Grand View Research, the global waterproofing products market was valued at approximately £7.4 billion in 2020.

What Are the Advantages and Disadvantages of a Seam Sealing Machine?

Advantages of a Seam Sealing Machine:

- Enhanced Waterproofing: By applying seam sealing tapes over stitched seams, seam sealing machines create a waterproof barrier, preventing moisture from entering and making the product more reliable in extreme weather conditions.

- Increased Durability: Sealing seams increases the lifespan of the product by preventing wear and tear caused by water damage. This is especially important for items like PPE seam sealing tapes, where product longevity and protection are critical.

- Improved Aesthetic Quality: Machines like the Teant Seam Sealer ensure that the sealed seams are uniform and neat, providing a clean and professional finish to the product.

Disadvantages of a Seam Sealing Machine:

- Initial Cost: High-quality seam sealing machines can be expensive, and the upfront investment can be significant. For small businesses, this could be a barrier to entry, but the long-term benefits usually outweigh the initial costs.

- Material Limitations: Not all fabrics are suitable for seam sealing, and some may require specific types of seam sealing tapes or machines. Ensuring compatibility between fabric and machine is essential for optimal results.

- Maintenance and Training: Regular maintenance is necessary to keep seam sealing machines running efficiently. Proper training ensures users operate the machine correctly, preventing defects in the sealing process.

Wrapping Up…

At Ardmel, we specialise in providing cutting-edge seam sealing machines that meet the diverse needs of manufacturers across various industries. Our machines consistently deliver high-quality sealing for commercial seam sealing tapes, PPE tapes, and cloth seam sealing tape, ensuring your products remain durable and reliable.

If you’re interested in learning more about seam sealing machines or would like to request a quote, get in touch with us today. Our expert team is here to help you find the best solution for your production needs.