The Advantages of Seam Sealing Machines

In the ever-evolving landscape of manufacturing and production, innovations in technology continue to redefine efficiency and quality.

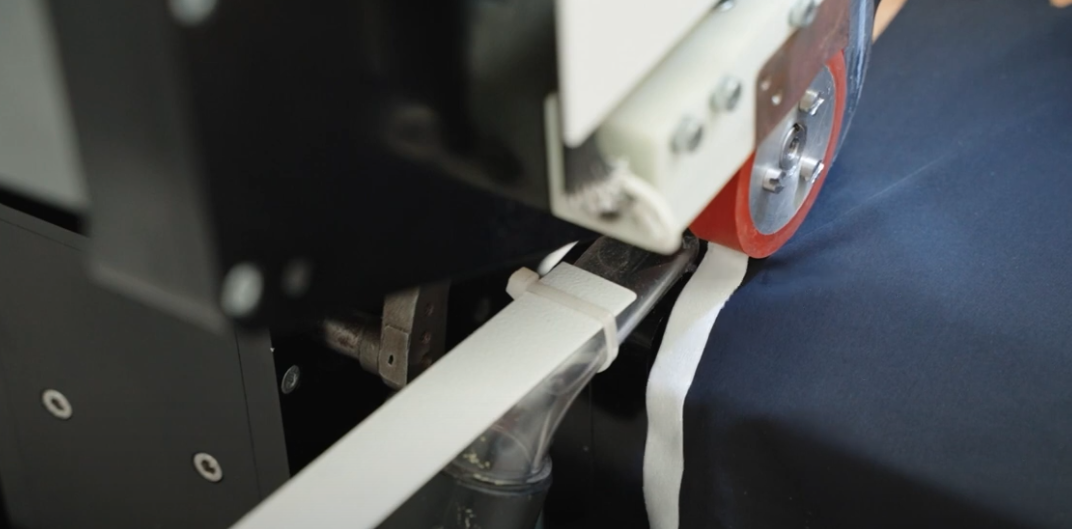

Seam sealing machines stand out as a testament to this evolution, offering a myriad of benefits across various industries. Whether in textile manufacturing, outdoor gear production, or medical equipment assembly, these machines play a pivotal role in enhancing product durability, waterproofing capabilities, and overall craftsmanship.

Enhanced Waterproofing

One of the primary benefits of seam sealing machines lies in their ability to enhance the waterproofing capabilities of various products. In industries like outdoor gear manufacturing (such as jackets, tents, and backpacks), medical equipment assembly, or even automotive production, the seams of products are critical areas where water can penetrate. Seam sealing machines utilize advanced technology to apply specialized sealants that create a water-resistant barrier, preventing leaks and ensuring the longevity of the product.

Improved Product Durability

Seam sealing machines contribute significantly to the overall durability of products. By creating a robust and watertight seal along seams, these machines help protect products from wear and tear, extending their lifespan. This is particularly crucial in industries where products are subjected to harsh environmental conditions, such as extreme weather or heavy usage.

Precision and Consistency

Unlike manual seam sealing methods, which may vary in quality and precision, seam sealing machines offer consistent and precise results. Automation ensures that every seam is treated uniformly, reducing the margin for error and enhancing the overall quality of the finished product. This consistency is invaluable in industries where product reliability and uniformity are paramount.

Time and Cost Efficiency

Seam sealing machines contribute to increased efficiency in manufacturing processes by reducing the time required for seam sealing. Automated machines can handle large volumes of products with minimal human intervention, streamlining production and reducing labour costs. The time saved in the manufacturing process can be redirected towards other essential tasks, ultimately improving overall operational efficiency.

Versatility in Applications

Seam sealing machines are versatile and can be adapted to various materials and product types. Whether working with fabrics, plastics, or other materials, these machines can be customized to meet the specific requirements of different industries. This versatility makes seam sealing machines an invaluable asset for manufacturers producing a diverse range of products.

Compliance with Industry Standards

In industries where regulatory standards are stringent, seam sealing machines play a crucial role in ensuring compliance. The consistent and reliable seam sealing provided by these machines helps products meet or exceed industry standards for quality, safety, and performance. This compliance not only enhances the reputation of manufacturers but also ensures that end-users receive products of the highest calibre.

Seam sealing machines represent a technological leap forward in manufacturing, offering a plethora of benefits that contribute to product quality, durability, and overall efficiency. As industries continue to evolve and demand higher standards, the adoption of seam sealing machines becomes a strategic imperative for manufacturers looking to stay competitive in their respective fields. Whether it’s waterproof outdoor gear, medical equipment, or automotive components, the benefits of seam sealing machines are undeniable, providing a reliable and cost-effective solution to enhance product performance and customer satisfaction.