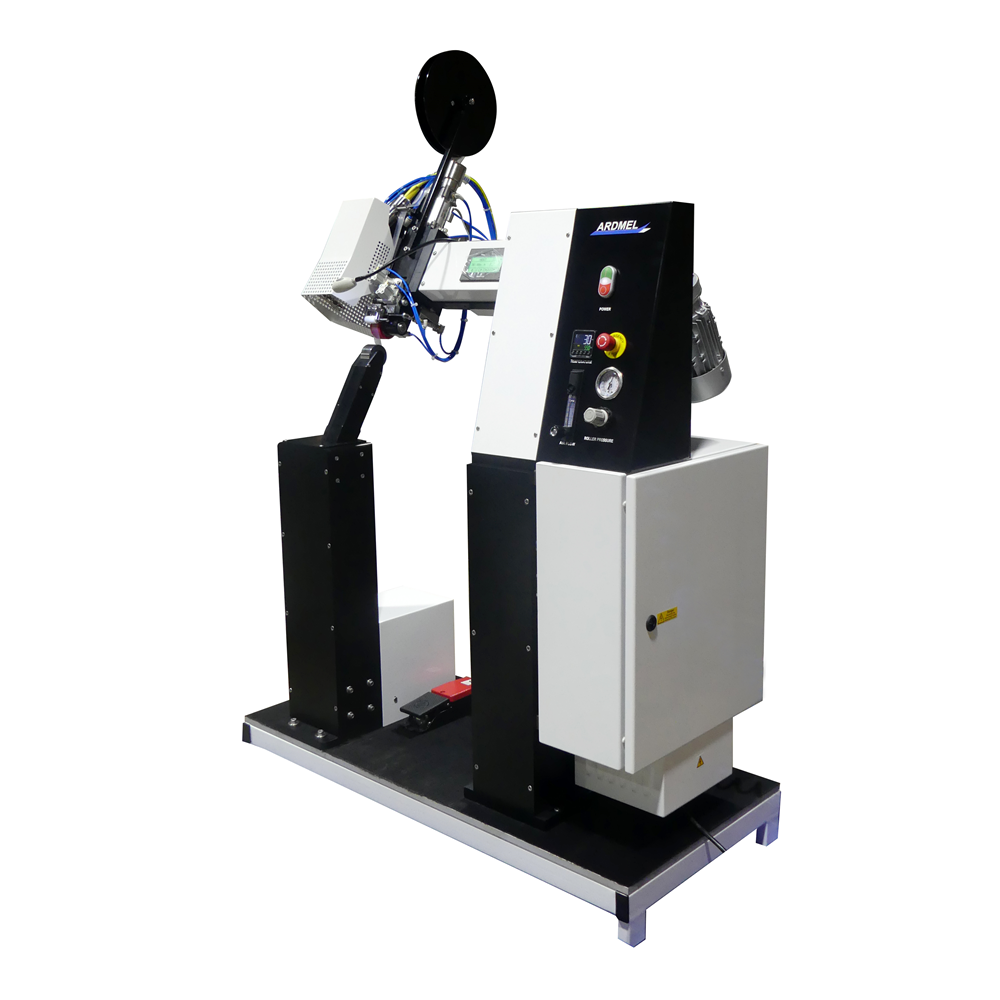

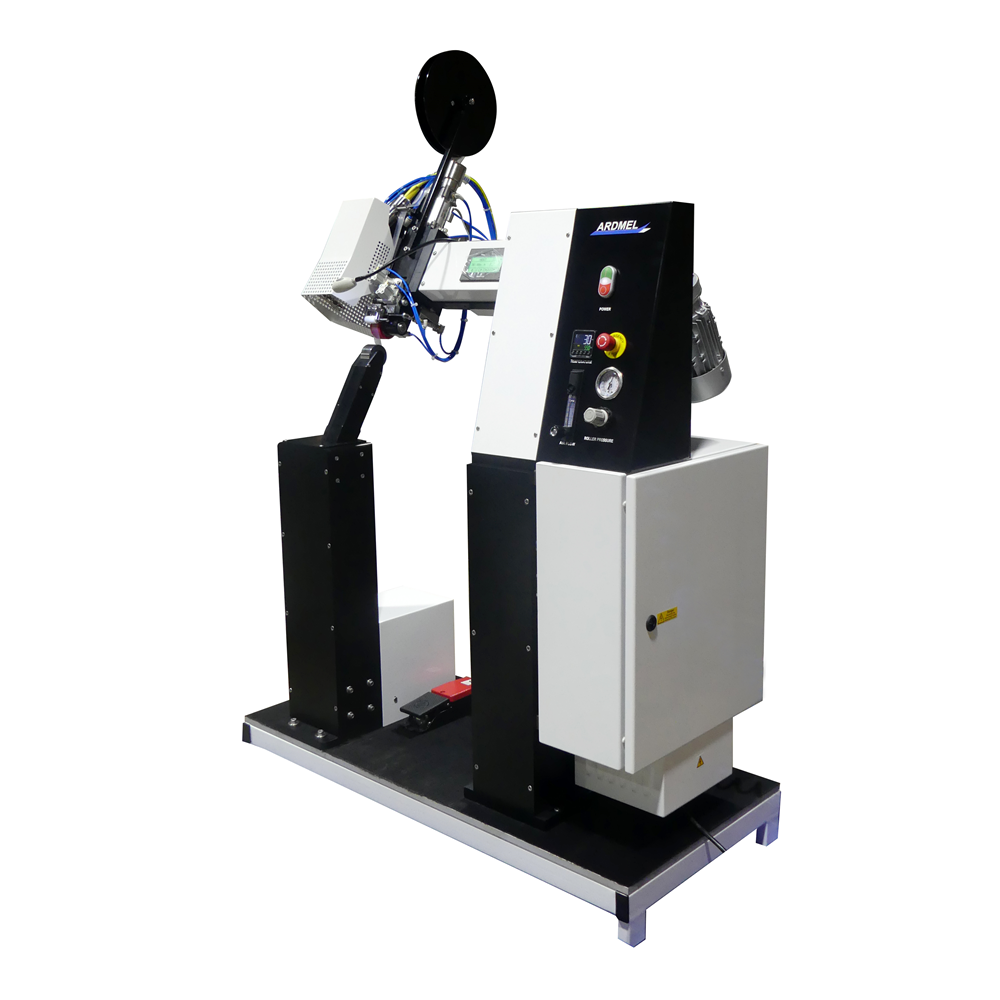

MK-950 Seam Sealing Machine

Provides ease of operation, consistency and quality with a range of attachments and added eco credentials.

Featuring a user-friendly touch-screen HMI with multi-language support, adjustments can be swiftly executed. The upgraded Control System now incorporates temperature and air supply feedback mechanisms.

Consequently, should the temperature fall out of range or there be an air supply failure, the machine will automatically cease operation or shut down the heater. This system is particularly well-suited for handling large or wide-ranging products such as tents, balloons, and sizable bags.

Not sure which version you need? Our expert team can help you identify the most effective attachments for your needs

Max Weld Temp: 750°C

Speed: 11m/min

Power Requirements: 230 V AC 50 Hz single phase, or 110 V AC 60 Hz

Compressed Air: 142l/min, 90 psi (min), 120 psi (max), 5 CFM, 6.2-8.2 Bar, 152l/min

Roller Width: 28mm (standard)

Weight: 147kg

Choose options

Features

Auto Scissors

Use: Permits speed reduction for sealing cross-over seams on 3-layer materials, optimising control without interrupting the manufacturing process

Benefit: Enhances efficiency by eliminating the need for separate hot stamping in these areas, streamlining the overall production workflow

Slack Feed Tape Device

Use: Allows unrestricted tape feed, reducing the risk of puckering and creasing in the sealed seams

Benefit: Enhances the quality of the final product by ensuring smooth and even tape application without distortions

Nozzle Guard

Use: Includes an air cooled nozzle guard, eliminating the necessity for the operator to wear gloves, and helps prevent fabric scorching

Benefit: Enhances operator comfort and safety, promoting a more ergonomic and user-friendly working environment

Differential Drive

Use: Allows the machine to compensate for soft, stretch or difficult fabrics, along with handling multiple layers simultaneously

Benefit: Ensures the seam stays smooth and does not pucker

Depth Stop Cylinder

Use: Facilitates the accommodation of thicker materials, such as neoprene, whilst also giving a flat finish on stretch and thinner fabrics

Benefit: Expands the versatility of the machine, enabling the effective sealing of a broader range of materials, thus enhancing the system’s adaptability. Additionally, it can regulate demarcation caused by pressure

HMI Touchscreen

Use: Input data through the touchscreen HMI panel designed for easy programming

Benefit: Simplifies user interaction and programming, ensuring user-friendly operation and efficient machine setup

See the MK-950 in action

Get extra functionality with our

Optional Attachments

Slim Quill

Eases tape application around tight corners

Reflective Kit

Available in 35mm or 50mm, it simplifies the application of wider retro-reflective tapes, ideal for workwear and outerwear

Need help?

Frequently Asked Questions

No! Our expert team work with many customers helping them take their initial idea through to a final product.

Yes, we can ship to many global destinations, and have agents available to help you with the details.

Yes, we manufacture a wide range of consumables for many different specialisms - our team can work with you to identify the one which will work best for you